AC Torque Motors

Bodine AC torque motors are designed to run at stall or produce reverse torque intermittently at reduced voltage. Torque decreases steadily as the rotor speed increases. They are ideal for tensioning applications such as coating equipment, web printers, and applications that wind film or wire, where they are frequently used on the take-up reel. When the reel is empty it rotates at its highest speed, but does not require much torque. When the reel is full, it rotates at a low speed and requires more torque. In applications such as these where material is wound or unwound continuously at a constant speed the motor acts like an “electronic spring,” maintaining constant tension while the diameter of the winding spool changes.

A step-down transformer or an inverter with single-phase output can be used to vary the supply voltage AC torque motors. For Type K-2 motors a power resistor wired in series with the motor can be used.

Bodine offers four AC torque motor frame sizes: 30R, 42R and 48R and K2. Torque ranges from a minimum of 0.2 lb-in to 4.1 lb-in, speed from 1360 to 1560 rpm, and power from 0.016 to 0.161 hp.

- Ideal for tensioning applications

Search by Specification (Parameter Search)

Filter By:

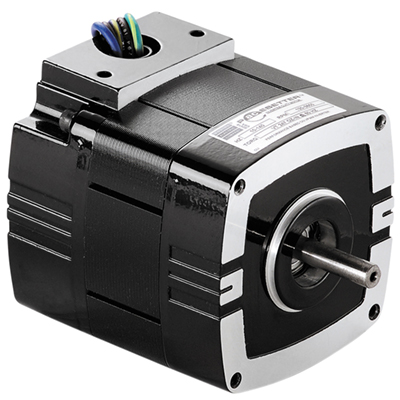

K-2 Series AC Torque Motor

Speed / RPM: 1300 to 1580

Torque: 0.2 to 0.4 lb-in

Power / HP: 0.016 to 0.029

30R Series AC Torque Motor

Speed / RPM: 1425 to 1660

Torque: 1.2 to 1.6 lb-in

Power / HP: 0.036 to 0.052

42R Series AC Torque Motor

Speed / RPM: 1435 to 1690

Torque: 1.4 to 2.4 lb-in

Power / HP: 0.063 to 0.114

48R Series AC Torque Motor

Speed / RPM: 1360 to 1560

Torque: 2.0 to 4.1 lb-in

Power / HP: 0.078 to 0.161