Custom Solutions

With over 1500 stock models and an infinite number of modifications possible, Bodine Gearmotor Experts can create a custom solution that precisely meets your requirements. Browse the common options listed below and then talk to an Application Engineer to start the process. Minimum order requirements are based on the complexity of your modifications.

Some Common Modifications Are Described Below

- Cables

- Gearing

- Gearboxes

- Mounting

- Output Shaft

- Rotor/Armature

- Winding

- Add-ons such as terminal boxes, brakes, encoders, and sprockets

DC Motor Winding changed for a different Voltage and/or Speed

Most Bodine DC motors have the option for a different armature winding for either a different voltage or a different speed. Since the voltage and speed of a DC motor are intertwined, it is actually possible to change both ratings without even changing the winding itself. For example, one of Bodine’s stock 130 VDC motors rated for 2500 rpm can also be called a 90 VDC motor rated for 1725 rpm. In this case, if the customer really wants the motor to be nameplated for 90 VDC, then all that needs to be changed is the nameplate. But, if the customer needed the opposite, like a 90 VDC motor that runs at 2500 rpm instead of 1725 rpm, then that would require a different winding, with a different number of turns and/or wire gauge. Read this story about how Bodine changed a DC motor winding to achieve a wider speed range in a conveyor pizza oven:

Gearmotors with Special Winding Design for Extended Speed Range

AC Motor Winding changed for a different Voltage and/or Frequency

Most Bodine AC motors have the option for a different stator winding for a different voltage and/or frequency rating. The alternate winding may have a different number of turns and/or a different wire gauge. If a certain Bodine AC motor is stocked with a 115 VAC rating, but the application requires operation from 230 VAC, then the different winding might be specified. If the application requires operation in a country where the line frequency is 50 Hz instead of 60 Hz, then a different winding might be specified for that as well. For ultimate flexibility, a winding might be specified for both dual voltage and dual frequency, as in 115/230 VAC, 50/60 Hz.

AC Motor Winding changed for a different Speed

Most Bodine AC motors have the option for a different rotor speed by changing the number of magnetic poles in the winding. Most Bodine nonsynchronous stock models have 4 poles and a rated speed of 1700 rpm at 60 Hz. Reducing the number of winding poles from 4 to 2 poles doubles the speed to 3400 rpm. Increasing the number of poles reduces the speed.

AC Motor Rotor Core changed for Higher Stall Torque

Some Bodine AC motors have the option of an alternate aluminum material grade used in the casting of the rotor core. The alternate material is used when “high slip” between the rotating magnetic field in the stator and the rotation of the motor shaft is desirable. This results in higher stall or starting torque and is used for that purpose in Bodine’s stock AC torque motors

AC Motor Rotor Core changed for Synchronous Speed

If you need two motors to run at precisely the same speed despite small differences in loading, we can build an AC motor with an alternate rotor core lamination. This kind of lamination has notches or flats to produce areas of high reluctance. The result is “no slip” between the rotating magnetic field in the stator and the rotation of the motor shaft. The motor speed will be synchronous with the line frequency at any load below or up to the motor rating. Read how one Bodine customer used a synchronous rotor core to match the speed of two 3-phase gearmotors driven from a single inverter:

Installation of an Encoder

Installing an encoder is a quick way to turn a standard motor into a “servo” motor. We have many accessory-ready stock models with a motor shaft extension and mounting holes on the motor endshield for field installation of commonly available encoders. For high volume OEM applications, though, it can be tedious to unpack, install, and then test the operation of hundreds of encoders. We can deliver motors pre-assembled with encoders. In some cases, we can even install the encoders inside the motor housing and make them invisible to the user. Read this story about how Bodine added an internal encoder to a DC motor to turn it into a “servo” motor for a self-steering tractor:

DC Motor with Internal Encoder

Installation of a Terminal Box

Terminal boxes are frequently used on our stock AC motors (most have flying leads) when IP44 environmental protection is required. Even though almost all Bodine stock DC motors come with a cord, a terminal box can be installed when a longer cord is needed. Many of our stock models have mounting holes for field installation of our terminal box kit, but for high volume OEM applications we can provide motors with the terminal box already attached. Read this story about how Bodine added a terminal box onto an AC gearmotor used on a packaging machine in a wet environment:

Installation of a Holding Brake

For high-volume OEM applications, we can install and test brakes right at our factory in Peosta, saving you the trouble of buying hundreds of brakes, unpacking, installing and then testing each one of them. For lower-volume applications, many of our stock models are accessory ready with a motor shaft extension and mounting holes on the motor endshield for field installation of commonly available brakes. The most common type of brake for motor applications is a power-off (failsafe) spring-applied electromagnetic brake. Read this story about how a brake is used on a Bodine gearmotor to hold a boat lift in place:

Bodine CG Gearmotors Lift Up To 10,000 lbs

Different Brushes for different Loading Conditions

The brushes used in Bodine’s stock DC motors are designed to provide the longest life at the rated current and speed of the motor. Sometimes, our general-purpose stock motors are used in very specific applications where they might be operated at either lower or higher currents than their rating, or at lower or faster speeds than their rating. That can result in either rapid brush wear or rapid commutator wear or objectionable noise. Read this story about how Bodine made the motor in a table-top testing device quieter for a specific loading condition by changing the brushes:

Custom Output Shaft Dimensions and/or Materials

As the component that transfers power from the gearbox to the driven load, driveshafts are one of the most modified parts of a gearmotor. We supply OEM customers with precision machined driveshafts with a wide variety of diameters, hollow bores, threads, tapers, keyways, etc. Read this story about how Bodine designed a very unique stainless steel hollow shaft on a DC motor used in a laboratory mixer:

Installation of Sprocket or Pulley on the Output Shaft

For a gearmotor to drive a load it needs to be attached to that load. Couplings, sprockets, pulleys and gears are readily available in sizes that fit Bodine’s standard shafts, but for high volume OEM applications we can deliver gearmotors with these components pre-installed. Read this story about how Bodine attached a crank arm and a gear onto the driveshafts of two different gearmotors used in a warehouse robot:

Custom Electrical Connections

Most of our standard gearmotors come with 12- or 24-inch lead wires with no connectors (the notable exception is our Brushless DC motors, which do have connectors), but that may not be right for your design. Bodine’s stock DC motors come with a cord. That cord may be made longer to reach the power source. Most of Bodine’s AC motors come with flying leads. By adding a terminal box, a more robust cord can be supplied instead. Adding a plug-in or twist-on connector to the end of the cord is easier said than done, because each connector manufacturer has their own unique tooling for crimping on the terminals that go into the connector. Bodine already supplies many types of connectors on our motors and we can help you choose one that we already have tooling for. Read this story about how Bodine provided a special cord with watertight connector on a gearmotors used outdoors:

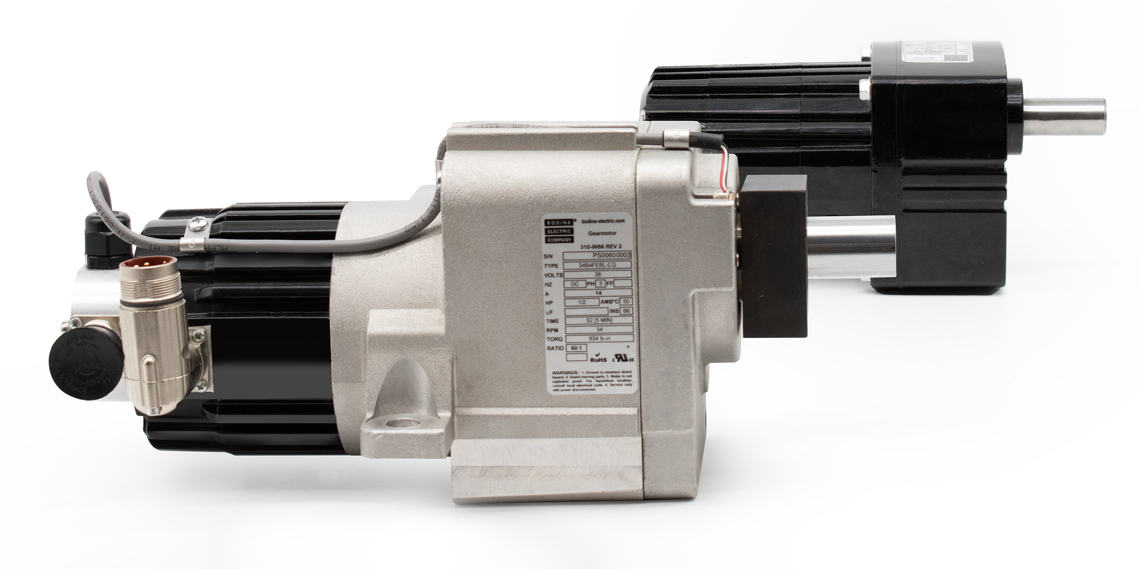

Gearmotor Delivers Precise Motion

Different Gear Ratio Combinations

Bodine stocks our gearmotors with many different gearing combinations to achieve a wide range of output speeds. But there are sometimes applications where the stocked gear ratio is not the best gear ratio.

One example is our double reduction gearmotor where the first stage has a worm gear and the output stage has a helical gear. Depending on the gear ratio, the worm gear may or may not be self-locking. If the stock ratio is not self-locking, but you need it to be, Bodine may change the combination in order to make it self-locking. For example, a 60:1 gear ratio normally using a 20:1 worm gearing stage that is not self-locking with a 3:1 helical gearing stage (20 X 3 = 60) might be swapped for a 30:1 worm gearing stage that is self-locking with a 2:1 helical gearing stage (30 X 2 = 60). Read this story about how Bodine did this very thing for a manufacturer of material handling lifts:

Changing Motor Construction for Use in Hazardous Locations

Bodine offers nearly 100 stock gearmotors that are certified for use in hazardous locations, but we don’t stock every possible motor/gearbox combination that way. For some customers, and for specific products, we can configure a variation of a stock product to allow certification in Class I Division II hazardous locations. Read this story about how Bodine configured one such AC gearmotor so that it could be certified for use in a C1D2 hazardous location for Cannabis Distillation:

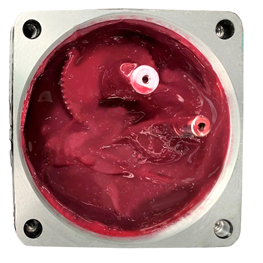

Changing Gearing Lubrication for Very Low Ambient Temperatures

Bodine’s stock gearmotors use a lubricant in the gearbox that is suited for a wide range of applications. But at very low temperatures the grease can solidify and put a heavier load on the motor trying to turn the gears. The motor may even stall. For these applications, Bodine can specify a different lubricant that remains viscous at the low temperatures. Note that at extremely low temperatures, problems with bearings arise and changing the gearing lubricant alone isn’t a complete solution. Read this story about how Bodine changed the gearing lubricant in a gearmotor used outdoors in northern climates for oil and gas production:

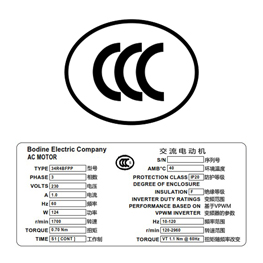

Adding Third Party Compliance Marks to the Motor Nameplate

All Bodine products are either UL Recognized or UL Listed. Most bear the CE mark for compliance to European standards. Testing and certification for other compliance marks can be a long and costly process. One exception is the Chinese Compulsory Certificate mark. Bodine has established a quick and inexpensive process for certifying most of our products to bear the CCC mark. Read this story about how Bodine added the CCC mark to our AC gearmotors for use in coating equipment destined for sale in China: