New Planetary PMDC Gearmotors Provide up to Twice the Torque!

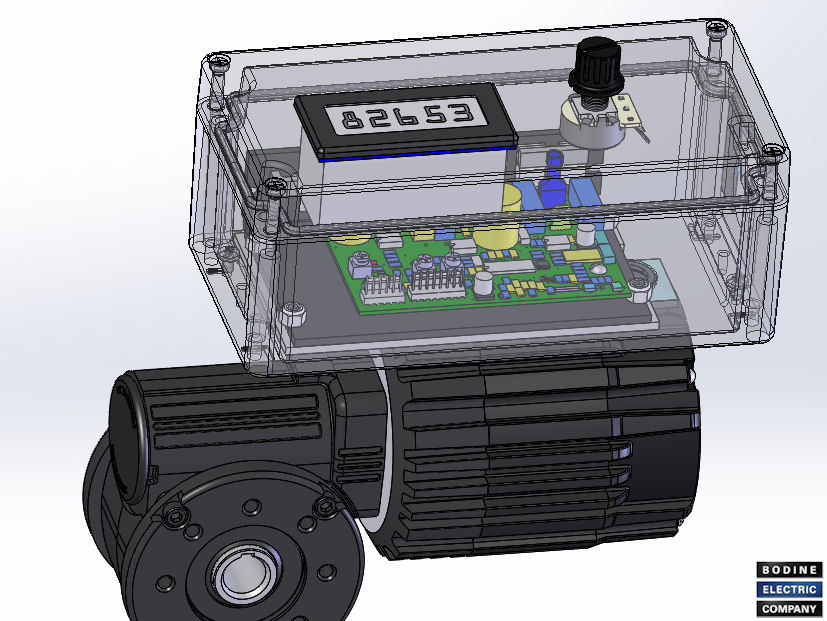

We are excited to introduce our new type 24A4-60P planetary gearmotors. This integral gearmotor design combines our high-performance type 24A PMDC motor with the all-new 60P (60mm) planetary gearhead. It is ideal for applications that require higher torque than conventional helical/spur gearheads of a similar size can provide, and where very low backlash gearhead isVIEW