Tag Archives: Brushless DC Gearmotor

Choosing the Right Gearmotor for Your Application

What is a gearmotor? A gearmotor consists of a small motor designed specifically with an integrated gear reducer (gearhead). The end shield on the drive end of the motor provides a dual function. The side facing the motor provides the armature/rotor bearing support and a sealing provision through which the integral rotor or armature shaftVIEW

Introduction to Fractional Horsepower Gearmotors – Tom’s Toolbox (Mi)

This video provides answers to questions like: What is a gearmotor? Why use FHP gearmotors? We talk about some of their main features and benefits, and we review the most common gearing and gearhead styles: parallel shaft, right angle, and planetary (center shaft) gearmotors.VIEW

Brushless DC Gearmotor Overview – Features and Benefits

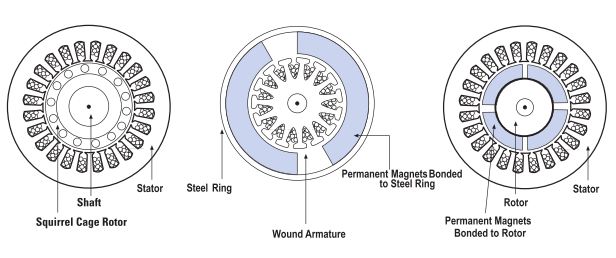

Brushless DC (EC) Gearmotors and Motors – What Is a Brushless DC Motor? Brushless DC motors could be called “inside-out permanent magnet motors” because brushless DC motors have their magnets on the rotating part of the motor instead of on the stationary part. Accordingly, they have their windings on the stationary part of the motorVIEW

Sizing a Fuse for a Bodine Gearmotor, Motor or Speed Control

Benefits of Fuse Protection 1. A fuse between the motor and AC line (to be used with single phase AC motors/gearmotors) provides motor protection under stall conditions and protects personnel from ground faults in the motor. It may not protect the motor from overheating under overload conditions. 2. A fuse between the motor and itsVIEW

Bodine 34B-WX Gearmotors Now Comply with Class I, Division 2 Standards for Use in Hazardous Locations

We now offer versions of our 34B4-WX brushless DC (EC) gearmotors that are ETL listed and comply with National Electrical Code Class I, Division 2 safety standards. Designed to reduce the risk of accidental fires or explosions in hazardous locations, these gearmotors can be used safely in environments such as petroleum refineries, dry cleaning plantsVIEW

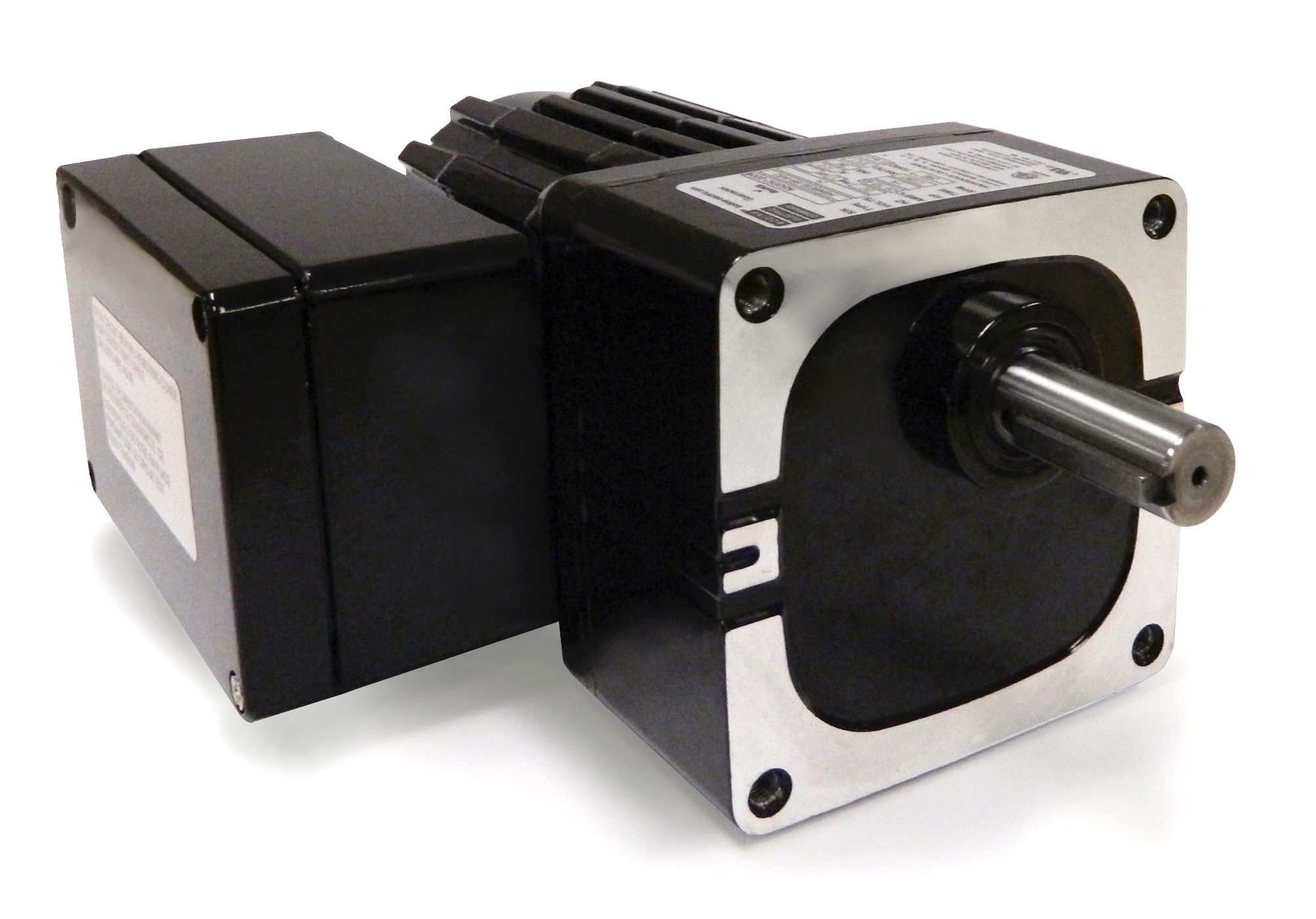

Low-Voltage, Right-Angle Brushless DC Gearmotor Combines Four Drive Components in One Compact Package

The new type 34B4/FV-5N gearmotors combine Bodine’s 34B brushless DC motor with a compact and cost competitive right-angle gearhead, a built-in PWM speed control, and an optical encoder. Together, they create a high-performance drive package that radically simplifies design, wiring, and assembly. The 24 VDC 34B/FV-5N gearmotors are ideal for a wide range of low-voltageVIEW

Introduction to Brushless DC (EC) Motor and Gearmotor Technology

Brushless DC Gearmotors and Motors In Section 3.1 of the Bodine Electric Handbook we discuss how motor action is achieved in a conventional permanent magnet DC (PMDC) motor. A segmented commutator rotating within a stationary magnetic field causes mechanical switching of the armature current. In a brushless DC (BLDC) gearmotor or motor, the magnetic fieldVIEW

New 34B/FV-F INTEGRAmotor BLDC stock gearmotors

We just added a new series of 24V brushless DC (ECM) gearmotors to our standard INTEGRAmotor™ product line. The new type 34B4/FV-F gearmotors combine a PWM speed control, a brushless DC motor, a high-torque gearhead, and an optical encoder into one high-performance drive package. The 34B/FV-F gearmotors provide 1/4 hp (187 watts) and up to 341 lb-in. (39 Nm)VIEW

Design Tips for Gearmotor Applications

To select the best gearmotor for an application, one must go into more detail than just selecting the best suitable output speed and torque. Here are five criteria you should consider. 1. Gearmotor Mounting Orientation Gearmotors are typically designed to be mounted with the gearbox level with the motor, and with the drive shaft inVIEW