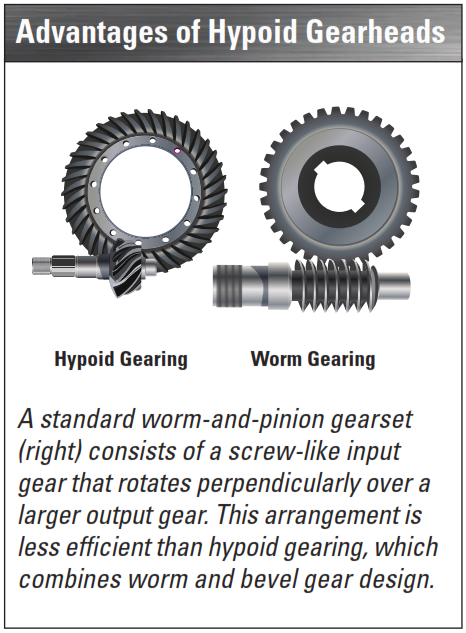

Right-angle gearmotors with hypoid gearsets have several advantages over standard worm and worm-gear gearmotors. While they cost more to manufacture, hypoid gearmotors are more efficient, produce less heat, provide higher torque, and are usually smaller than equivalent gearmotors with worm- and worm-gear reducers.

More Efficient at Low Speeds and High Reductions

Hypoid gears require less energy to begin rotation, making them more efficient at lower speeds. At higher reductions, because the hypoid tooth pattern allows torque to be transferred smoothly with less friction they can be 40% to 60% more efficient than their worm-gear counterparts. In some cases this can mean that a motor rated at 1/2 hp coupled with a hypoid gearhead can deliver the same amount of torque as a worm gearhead driven by a 1hp motor.

Cooler Operating Temperature

The hypoid gear design generates less friction between the gear teeth than worm-gears. Side-by-side tests have shown that hypoid gearmotors can run as much as 15% cooler than worm-and-pinion gearboxes driven by the same size motor. This can result in lower power consumption and better lubrication life.

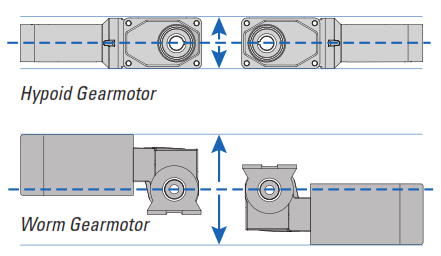

Smaller Footprint

Not only can hypoid gearmotors be driven by smaller motor for the same load, but the geometry of the gearing allows them to be mounted in line with the motor, while the worm gearheads must be offset. Combining these benefits results in a much smaller overall package size for a hypoid gearmotor than a comparable worm gearmotor.

Designed to Last

Worm gears are usually made from bronze, which is softer than steel. While hypoid gears cost more to manufacture than a simple worm gear set, they are typically made from heat-treated steel, which allows them to operate at peak efficiency for longest possible product life and quiet operation.

New Hypoid PMDC Gearmotors from Bodine

The new type 33A7-25H2 and 33A7-30H3 hypoid PMDC gearmotors combine our high-performance 33A7 PMDC motor with our all new hypoid gearheads. The gearmotors’ high torque and efficiency make them an ideal drive solution for applications that require compact size, lower energy consumption and cooler operation. The gearmotors are available with 12 gear ratios (5:1 to 240:1) and five winding options: 90 & 180VDC (“SCR Rated”), 130VDC and 12V or 24VDC, with a rated torque of up to 1535 lb-in (173 Nm). Optional accessories are: drive shaft kits, base/foot mount brackets, and our unique screw-in encoder shaft kit.

To download this article as a PDF, please click here.

Copyright Bodine Electric Company © 07/2020. All rights reserved.