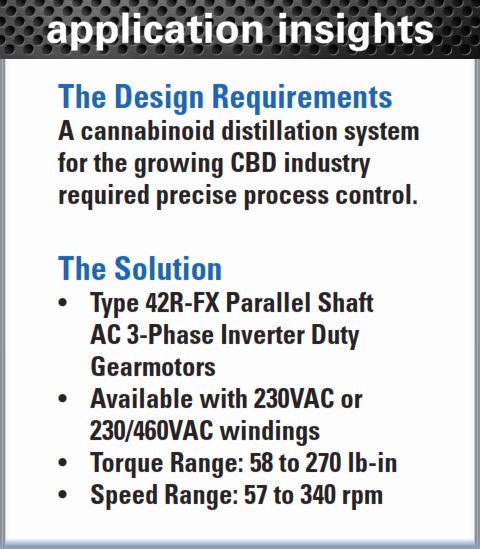

A manufacturer of CBD distillation equipment required a gearmotor to precisely control the flow and speed of liquid material through their new distillation apparatus.

click here for more info

Working with an authorized Bodine distributor and our sales team, the manufacturer selected several of our variable speed AC inverter duty gearmotors, combined with inverter drives (VFDs) and a PLC control to drive the pumps and stirring mechanism within the distillation system. Earlier versions of the equipment used a competitor’s brush-type DC motor and control system. By replacing them with Bodine AC inverter-duty gearmotors, the manufacturer eliminated both brush maintenance and the noise associated with brushed DC motors.

- Standard/Stock 42R-FX AC inverter duty gearmotors

- Eliminated brush maintenance reducing machine downtime

- Lowered operational noise

Now also available from Bodine: new Class I/Div 2 AC inverter-duty and fixed speed (PSC) 34R-FX gearmotors, and CI/Div1 “Explosion-Proof” AC inverter-duty and low-voltage BLDC type 34R-FX gearmotors and 34R6BX motors.

To download this blog post as a PDF, click here.

Copyright Bodine Electric Company © 10/2020. All rights reserved.