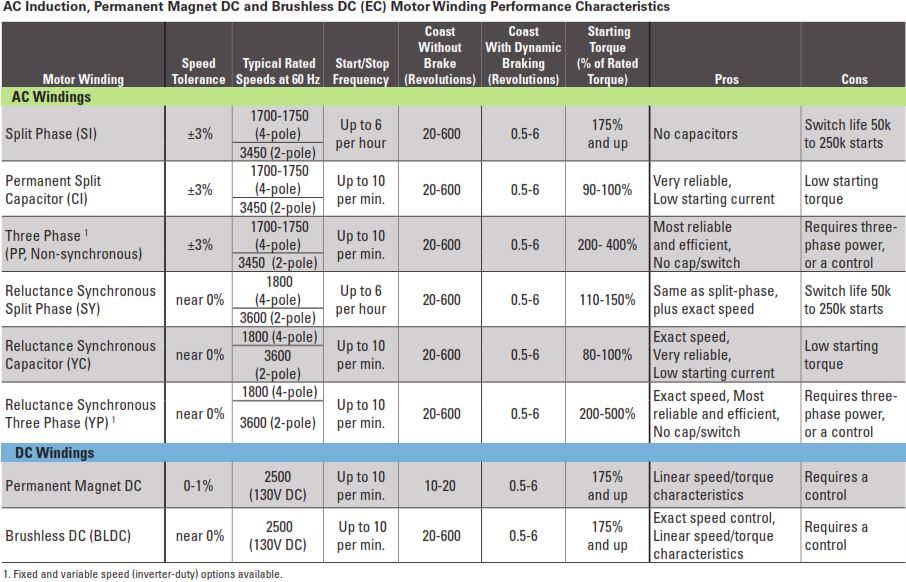

Winding design is one of the major factors that determines gearmotor performance. For example, the windings may be driven by AC or DC current. They may require a capacitor, or a control to run, and may be configured as single, split- or three-phase systems. Some motor types provide precise speed and position control, while others are less accurate. They may be built to run at either a constant or variable speed. Understanding these differences is critical to selecting the right gearmotor for your application.

As a manufacturer that exclusively focuses on fractional horsepower (less than 1 HP/746 Watts) products, Bodine Electric Company offers a range of standard gearmotors and motors with the most common voltage and frequency ratings for both the North American and International markets. Bodine Electric also has the engineering expertise to design and manufacture a great variety of custom winding types and ratings.

AC Induction

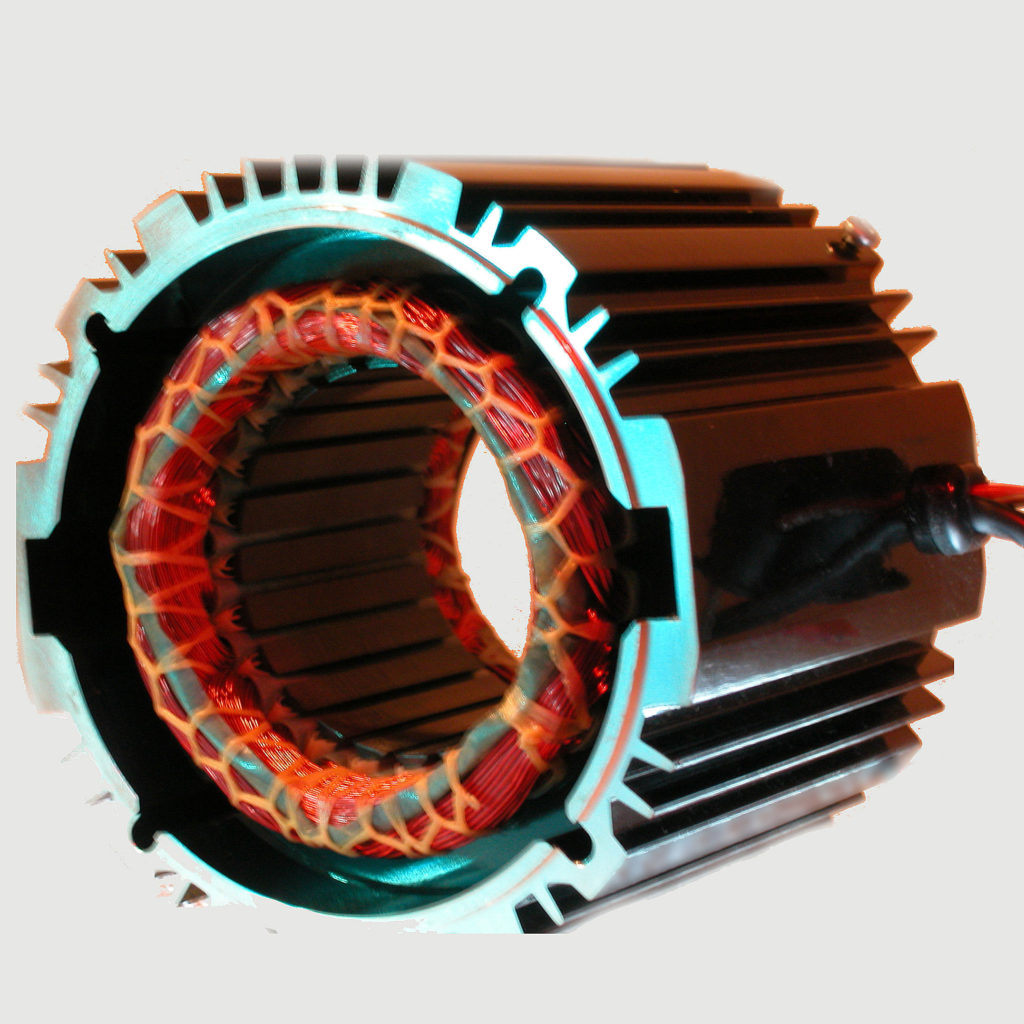

AC windings are available in single-phase, two-phase, and poly-phase (three-phase) designs including the following types; split-phase (with centrifugal start switch), capacitor start, permanent split capacitor, 2 capacitor start, 2 capacitor start / one capacitor run, and reluctance synchronous.

These windings can be produced in 2-, 4-, 6- & 8-pole configurations and can be rated as continuous duty, intermittent duty, inverter-duty, dual voltage, dual frequency and fixed or variable speed. Our AC windings are available in voltages ranging from 12 to 575 VAC. Bodine Electric Company also provides solutions for OEM applications that require thermal overload protectors with manual or automatic resets, or simple temperature limiting switches.

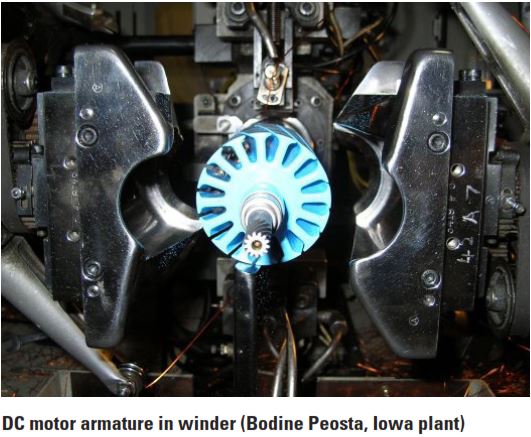

Permanent Magnet DC

PMDC motors are available with rated voltages from 12 to 240 VDC. They can be designed in 2 & 4 pole versions and in lap or wave (4 brush vs. 2 brush) configurations. Multiple magnet grades are available for enhanced performance or added demagnetization protection. End-of-life signaling brushes, and a new proprietary brush wear sensor system are also available from Bodine Electric Company.

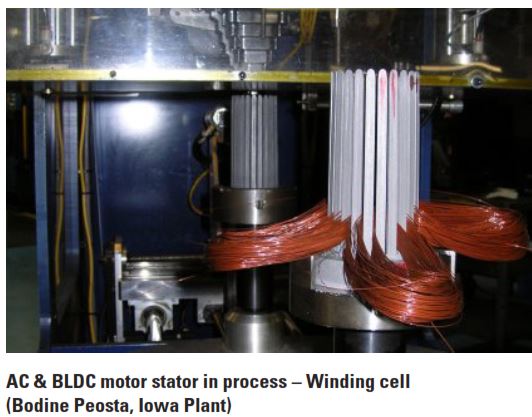

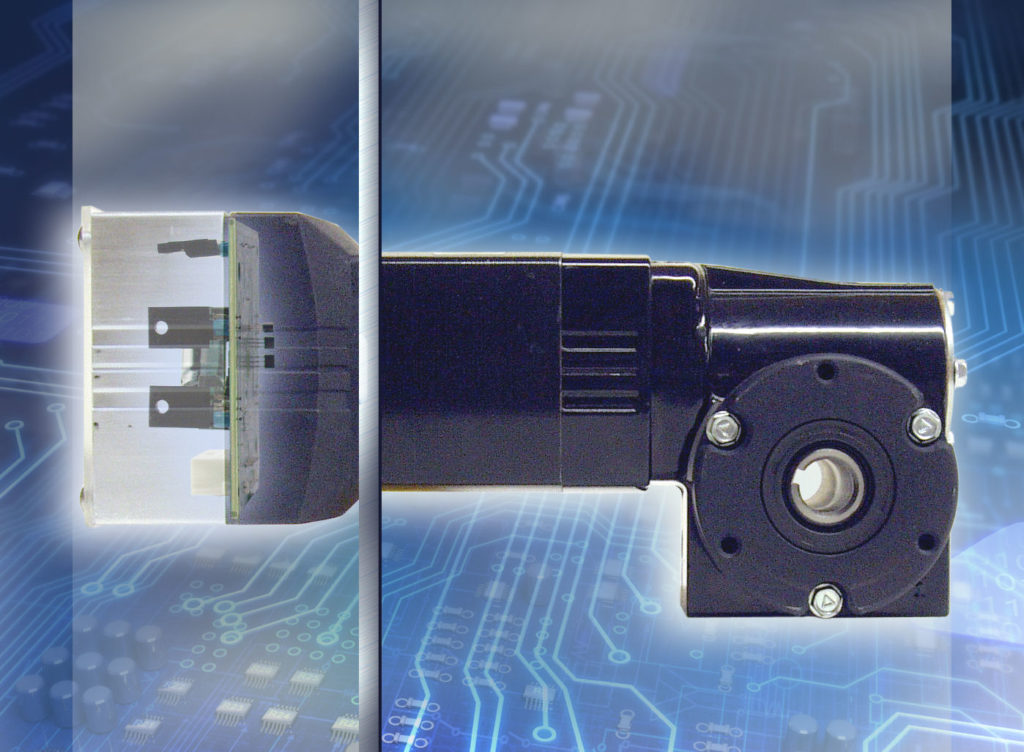

Brushless DC (EC)

Our standard brushless DC windings are 3-phase, 4-pole designs (standard voltages are 24 VDC and 130 VDC). Custom designs with voltages ranging from 12 VDC to 260 VDC, and horsepower ratings up to 1 HP/746 Watts, and 8-pole designs are also available. Commutation angle is 60 degrees (standard), and 120 degrees optional (standard on our stock 22B-60P planetary geared motors).

In addition, we also offer our unique 24 VDC INTEGRAmotor product line of brushless DC motors with built-in motor speed control and motor feedback device. Our type 22B/FV and 34B/FV INTEGRAmotors combine a 24VDC brushless DC motor, a built-in, open loop, voltage mode PWM controller and a 1024 PPR, two channel quadrature optical encoder. They accept PWM input from an external motion or speed controller, and feature amplifier enable, direction and dynamic braking inputs, as well as fault signal outputs. The Bodine type 22B/SR and 34B/SR motors and geared motors combine a 24VDC brushless DC motor with a built-in, 0-5 VDC analog input SR control.

If you would like to download this blog article as a PDF, click here.

Copyright Bodine Electric Company © 04/2020. All rights reserved.