Blog

Category Archives: Gearmotor Basics

What is a Synchronous AC Motor? Hysteresis- and Reluctance-Type Designs

The difference between the speed of the rotating magnetic field of an induction motor (which is always synchronous) and the speed of the rotor is known as “slip.” When the rotor design enables it to “lock into step” with the field, the slip is reduced to zero and the motor is said to run...VIEW

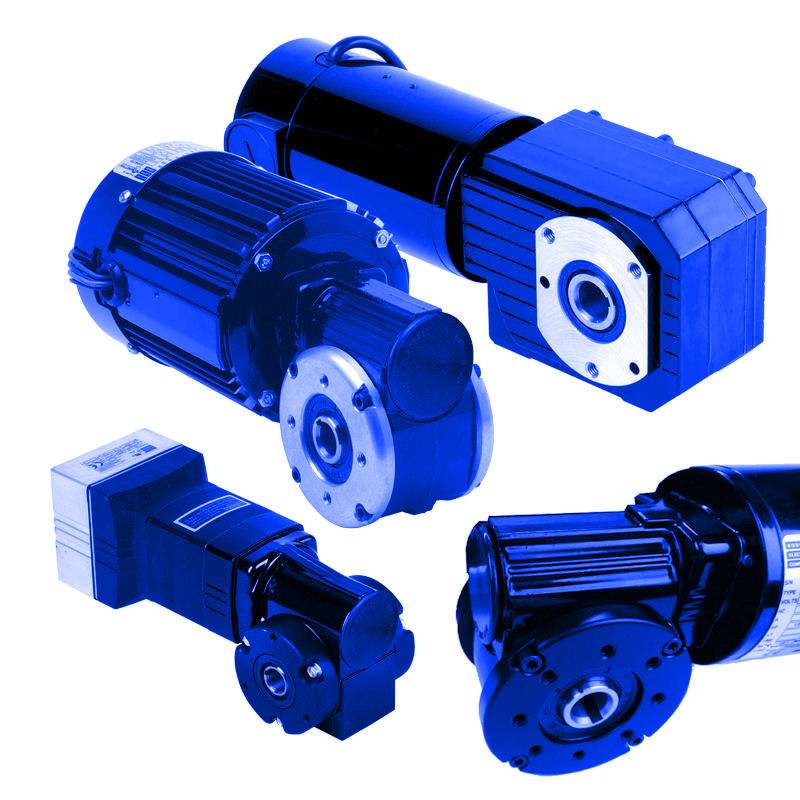

Single-Reduction Right-Angle “6RX” Gearmotors Fit in Tight Spaces

Available with three different permanent magnet DC motor options, the 6RX gearmotors are ideal for a range of industrial and mobility applications that require a very narrow gearhead. The 6RX gearhead is offered with our 37A and 42A PMDC motors and various high- and low-voltage winding options (12,24,90,130 and 180 VDC). The gearmotors are availableVIEW

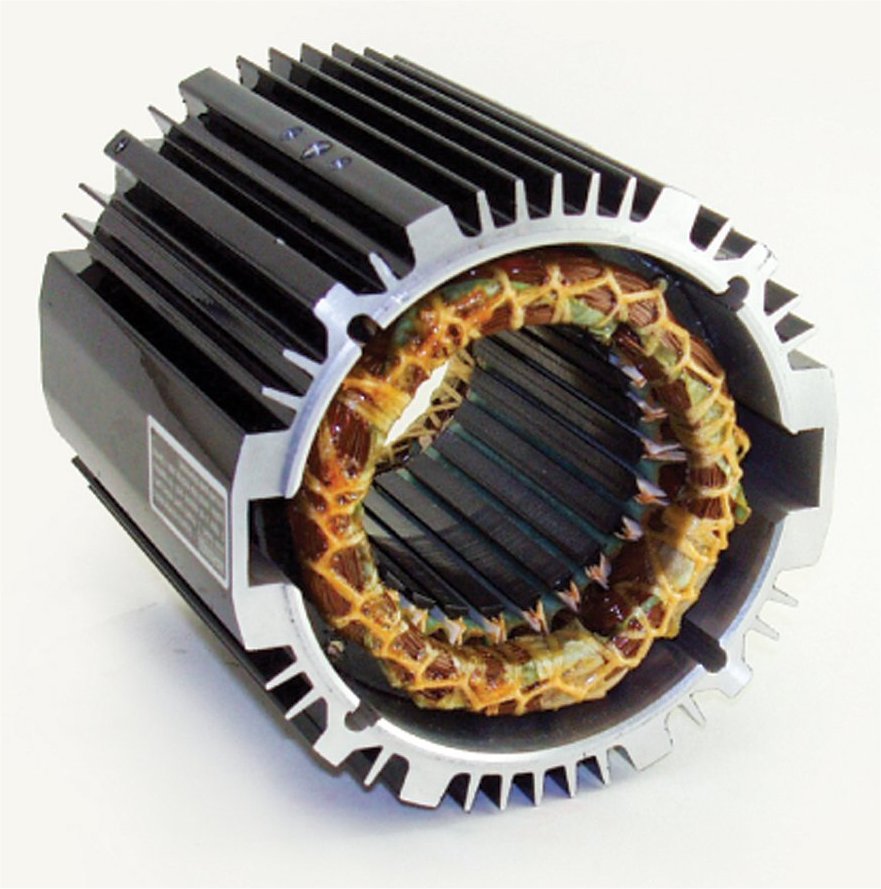

AC Induction Motors with Squirrel Cage Rotors

Why is it called a “squirrel cage rotor?”: Most fractional horsepower (FHP) AC induction motors utilize a die cast rotor design that consists of a skewed lamination stack with die cast rotor bars and end rings. The common term for this rotor design is “squirrel cage”, because if you remove the steel laminations after theVIEW

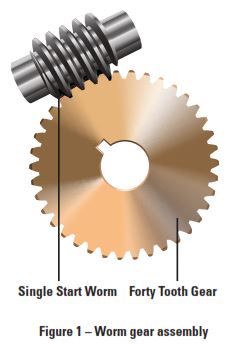

Introduction to Worm Gearing

Worm gearing is a proven and economical solution for applications that require high speed reductions in limited space, and with very smooth and quiet operation. Worm gears have inherent self-locking ability depending on design and ratio. Lubrication is very important for the life of the worm gear set and efficiency can be improved by usingVIEW

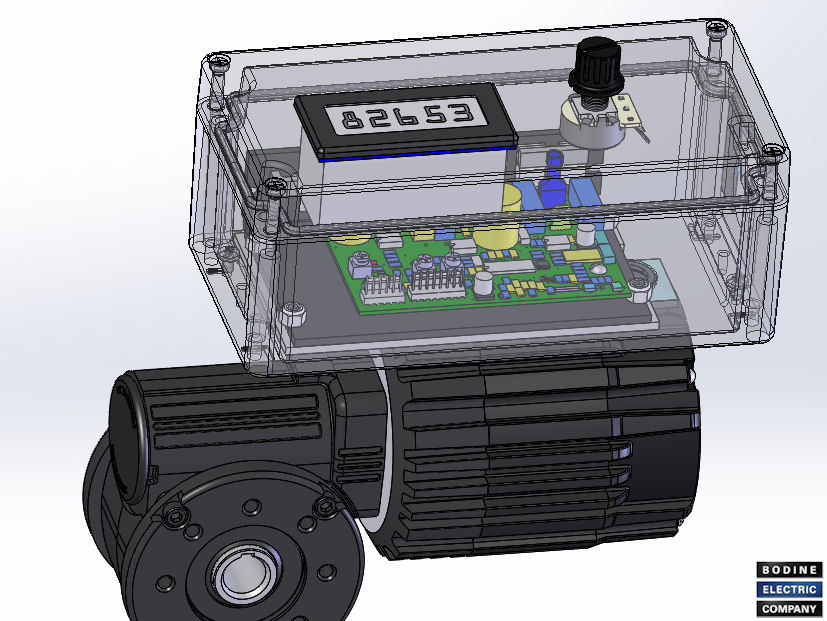

Choosing the Right Gearmotor for Your Application

What is a gearmotor? A gearmotor consists of a small motor designed specifically with an integrated gear reducer (gearhead). The end shield on the drive end of the motor provides a dual function. The side facing the motor provides the armature/rotor bearing support and a sealing provision through which the integral rotor or armature shaftVIEW