Blog

Category Archives: Engineering Talk

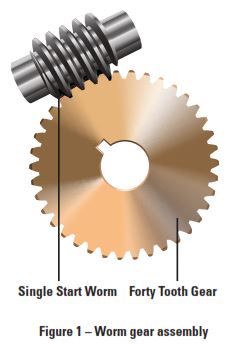

Introduction to Worm Gearing

Worm gearing is a proven and economical solution for applications that require high speed reductions in limited space, and with very smooth and quiet operation. Worm gears have inherent self-locking ability depending on design and ratio. Lubrication is very important for the life of the worm gear set and efficiency can be improved by usingVIEW

Choosing the Right Gearmotor for Your Application

What is a gearmotor? A gearmotor consists of a small motor designed specifically with an integrated gear reducer (gearhead). The end shield on the drive end of the motor provides a dual function. The side facing the motor provides the armature/rotor bearing support and a sealing provision through which the integral rotor or armature shaftVIEW

Bodine 24A and 42A Motors Successfully Pass UL’s IP-66 Test

OEM applications often require gearmotors and motors that exceed the design features of our standard products. But with over 110 years of design and application engineering experience with FHP motors and gearmotors, we can add and include special design features and modifications for those demanding OEM applications. One such example is our recent approval by Underwriters LaboratoryVIEW

Brushless DC Gearmotor Overview – Features and Benefits

Brushless DC (EC) Gearmotors and Motors – What Is a Brushless DC Motor? Brushless DC motors could be called “inside-out permanent magnet motors” because brushless DC motors have their magnets on the rotating part of the motor instead of on the stationary part. Accordingly, they have their windings on the stationary part of the motorVIEW

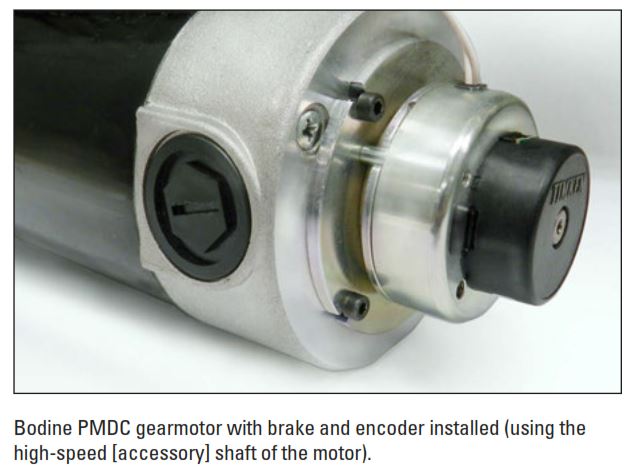

Electromagnetic Holding Brakes for Small Gearmotors and Motors

Holding, or “Power-Off,” brakes provide extra safety in applications where the load must remain in position in the event of power loss or equipment failure. Our design engineers have helped OEMs develop brake systems for hundreds of AC and DC applications, from home stairlifts to industrial applications. In this article, we focus on the principlesVIEW

Quiet Gearmotors for Medical Equipment

Gearmotors in mammography equipment are used to raise and lower the scanner to accommodate the patient’s height. The primary design objective is smooth and quiet operation. Our team of design engineers addressed four aspects of the gearmotor design that contribute to quiet operation. Worm Gearing Bodine recommended a right-angle gearmotor with worm gearing. The slidingVIEW

Model 2999 New Rugged AC Motor Speed Control

Bodine expands its extensive line of AC, PMDC, and BLDC speed controls with the new Model 2999. Featuring an industrial-grade NEMA-4X/IP-65 watertight aluminum die-cast enclosure, the model 2999 drives 230 VAC, 50 or 60 Hz, inverter-duty, 3-phase gearmotors rated up to 1 HP (746 W). It operates from single-phase 115 or 230 VAC, and itVIEW

Sizing a Fuse for a Bodine Gearmotor, Motor or Speed Control

Benefits of Fuse Protection 1. A fuse between the motor and AC line (to be used with single phase AC motors/gearmotors) provides motor protection under stall conditions and protects personnel from ground faults in the motor. It may not protect the motor from overheating under overload conditions. 2. A fuse between the motor and itsVIEW

3D Printing/Additive Manufacturing in Gearmotor Design and Manufacturing

In keeping with our Quality Policy and our dedication to Continuous Improvement, Bodine Electric’s manufacturing and engineering teams joined forces in 2013 to identify and source a 3D printing solution that fits our needs. The creation of physical prototypes of new castings or moldings or any new part has traditionally been a challenge in theVIEW