Blog

Category Archives: Custom Solutions

Bodine 24A and 42A Motors Successfully Pass UL’s IP-66 Test

OEM applications often require gearmotors and motors that exceed the design features of our standard products. But with over 110 years of design and application engineering experience with FHP motors and gearmotors, we can add and include special design features and modifications for those demanding OEM applications. One such example is our recent approval by Underwriters LaboratoryVIEW

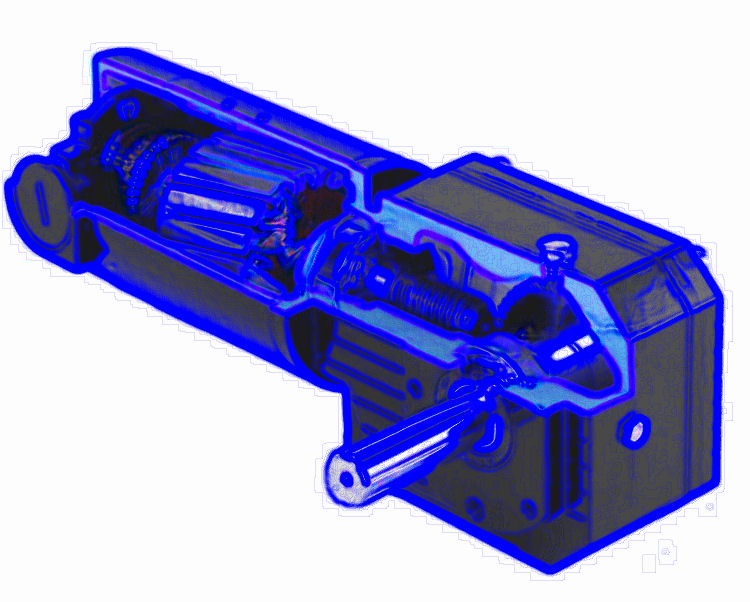

Electromagnetic Holding Brakes for Small Gearmotors and Motors

Holding, or “Power-Off,” brakes provide extra safety in applications where the load must remain in position in the event of power loss or equipment failure. Our design engineers have helped OEMs develop brake systems for hundreds of AC and DC applications, from home stairlifts to industrial applications. In this article, we focus on the principlesVIEW

Quiet Gearmotors for Medical Equipment

Gearmotors in mammography equipment are used to raise and lower the scanner to accommodate the patient’s height. The primary design objective is smooth and quiet operation. Our team of design engineers addressed four aspects of the gearmotor design that contribute to quiet operation. Worm Gearing Bodine recommended a right-angle gearmotor with worm gearing. The slidingVIEW

3D Printing/Additive Manufacturing in Gearmotor Design and Manufacturing

In keeping with our Quality Policy and our dedication to Continuous Improvement, Bodine Electric’s manufacturing and engineering teams joined forces in 2013 to identify and source a 3D printing solution that fits our needs. The creation of physical prototypes of new castings or moldings or any new part has traditionally been a challenge in theVIEW

Bodine 34B-WX Gearmotors Now Comply with Class I, Division 2 Standards for Use in Hazardous Locations

We now offer versions of our 34B4-WX brushless DC (EC) gearmotors that are ETL listed and comply with National Electrical Code Class I, Division 2 safety standards. Designed to reduce the risk of accidental fires or explosions in hazardous locations, these gearmotors can be used safely in environments such as petroleum refineries, dry cleaning plantsVIEW

Low-Voltage, Right-Angle Brushless DC Gearmotor Combines Four Drive Components in One Compact Package

The new type 34B4/FV-5N gearmotors combine Bodine’s 34B brushless DC motor with a compact and cost competitive right-angle gearhead, a built-in PWM speed control, and an optical encoder. Together, they create a high-performance drive package that radically simplifies design, wiring, and assembly. The 24 VDC 34B/FV-5N gearmotors are ideal for a wide range of low-voltageVIEW

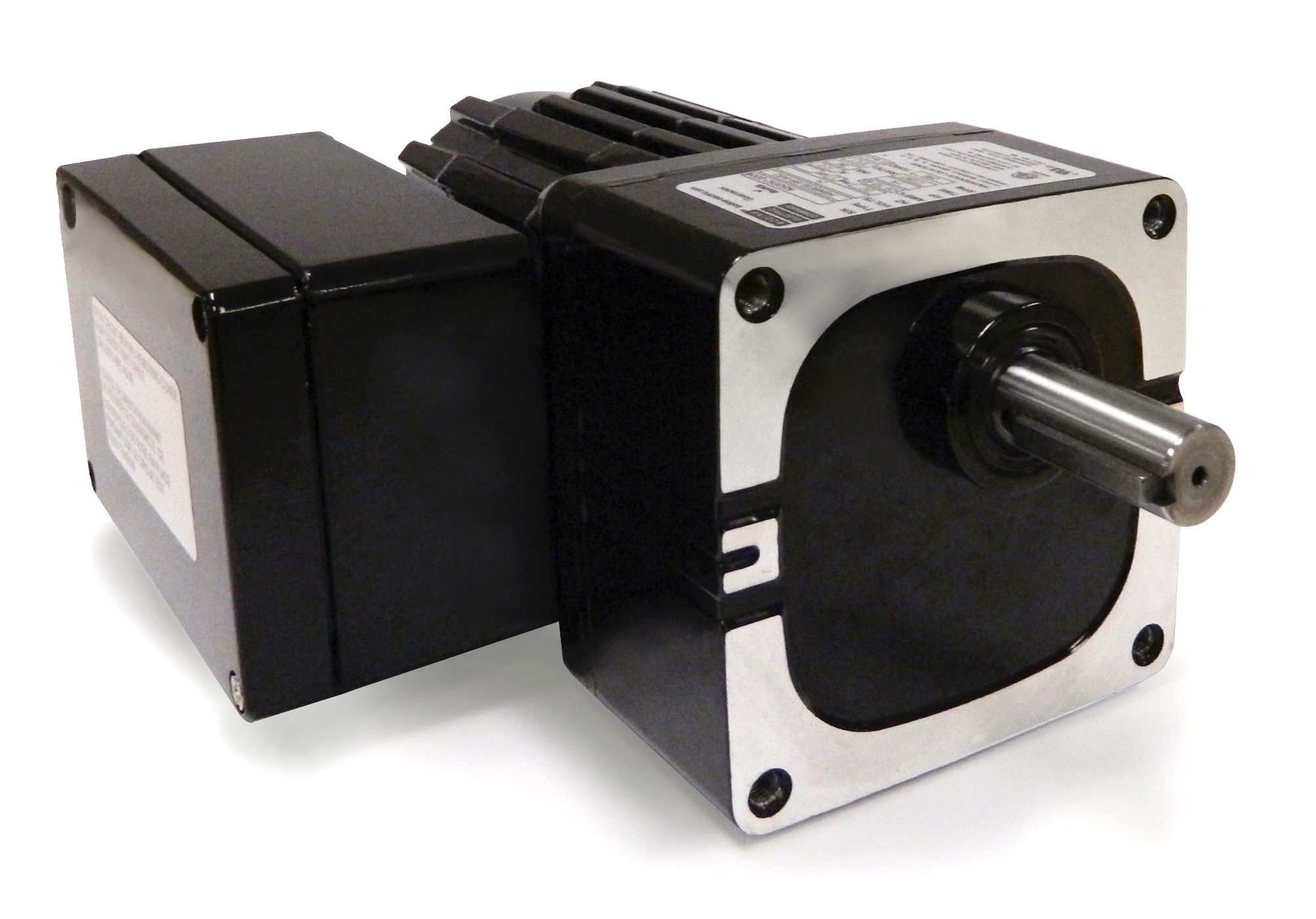

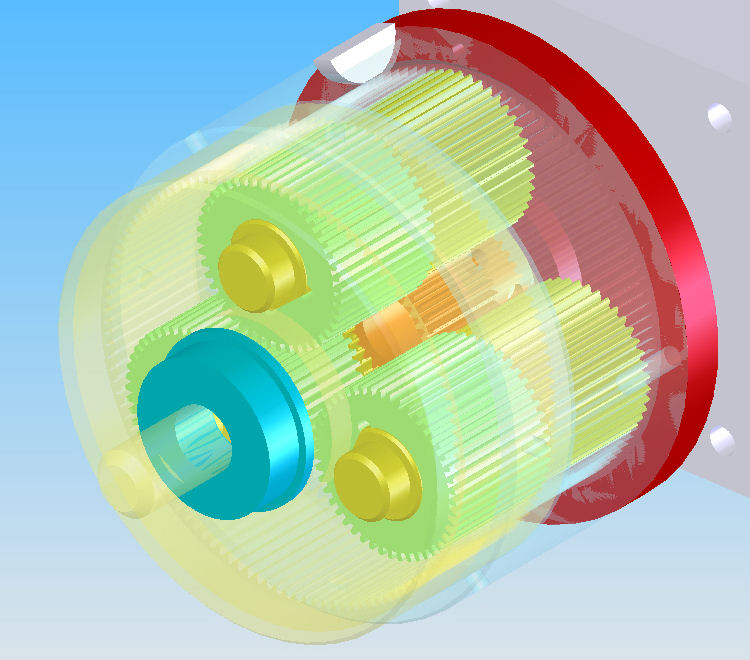

Advantages and Disadvantages of Planetary Gearmotors

We design all our standard parallel shaft (helical or helical/spur) and right angle (worm or helical/worm) gearboxes in-house, and all gearheads are manufactured and assembled in our main factory in Iowa. Occasionally, we’ll receive a request to mate one of our standard AC, DC or BLDC motors to a planetary gearhead. To identify the best gearmotor option for our customer’sVIEW

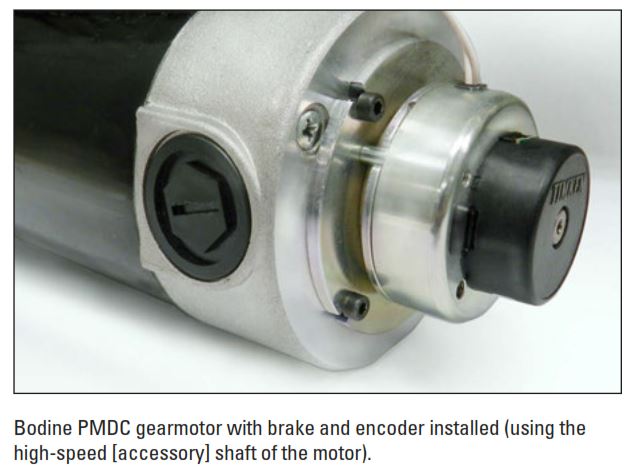

Permanent Magnet (PM) DC Gearmotors and Motors

Features and Benefits of PMDC Gearmotors and Motors: Continuous duty operation DC power supply (battery or speed controls – 12/24V, 90/130V, 180V) Reversibility at rest or during rotation with current limiting Relatively constant and adjustable speed Starting torque 175% and up of rated torque High starting current, relative to full load running current Design andVIEW