Brushless DC Gearmotors and Motors

In Section 3.1 of the Bodine Electric Handbook we discuss how motor action is achieved in a conventional permanent magnet DC (PMDC) motor. A segmented commutator rotating within a stationary magnetic field causes mechanical switching of the armature current. In a brushless DC (BLDC) gearmotor or motor, the magnetic field rotates. Commutation occurs electronically by switching the stator current direction at precise intervals in relation to the position of the rotating magnetic field. Solid state controls and internal feedback devices are required to operate brushless DC motors (also called: electronically commutated “EC” motors).

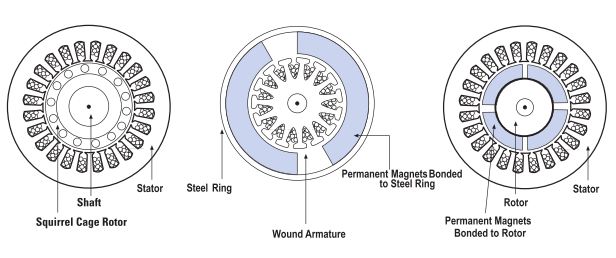

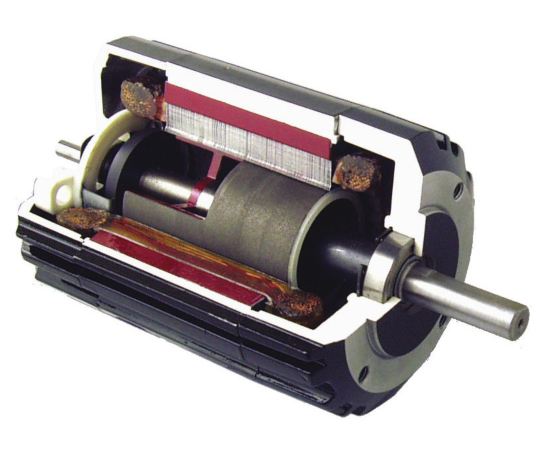

Fig. 3-12: Cross-sections of: a) an AC induction motor (left), b) a PM DC motor (center), and c) a brushless DC motor (right).

Brushless DC motors combine characteristics of both DC and AC motors. They are similar to AC motors in that a moving magnetic field causes rotor movement or rotation. They are similar to DC motors since they have linear speed-torque performance characteristics. Figure 3-12 shows cross-sections of AC induction, permanent magnet DC and brushless DC motors. The AC motor has windings in the stator assembly and a squirrel cage rotor. The PMDC motor has windings on the rotor assembly and permanent magnets for the stator assembly. The brushless DC motor is a hybrid of the AC and DC motors. The rotor has permanent magnets and the stator has windings.

Brushless DC Motor Technology

Features & Benefits:

- Ideal for continuous duty applications

- Reversibility at rest or during rotation (with current limiting)

- Delivers rated torque over full speed range

- Starting torque 175% and up of rated torque (consider gear strength limits)

- Quiet and reliable operation; No brush maintenance!

- BLDC motors require a speed control

- Built-in tach pulse output for economical speed read-out; Encoders optional

- Thermally more efficient than PMDC motors. Higher performance than AC motors.

- Standard Bodine BLDC products feature 60° commutation (120° is a custom option)

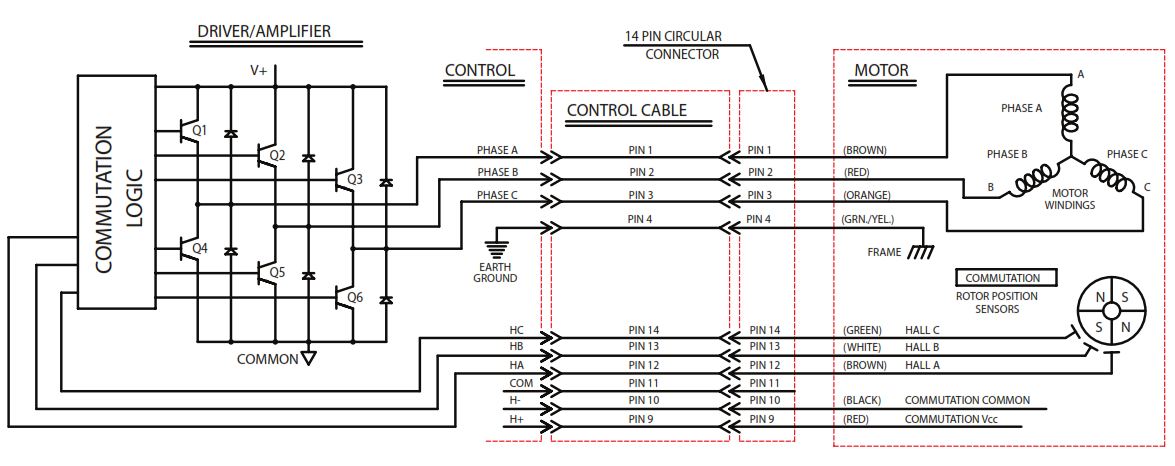

Design and Operation: Brushless DC motors (see Fig. 3-13) consist of two parts: the motor and a separate electronic commutator control assembly. The two must be electrically connected with a cable or wiring harness before motor action can take place. See Fig. 3-14.

Fig. 3-14: Schematic diagram of a brushless DC motor and control.

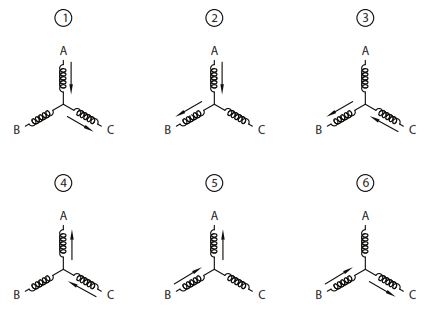

By energizing specific windings in the stator, based on the position of the rotor, a revolving magnetic field is generated. See Fig. 3-15. Sensors mounted inside the motor detect the position of the permanent magnets on the rotor. For example, as the rotor moves through a specific angle or distance, one of the sensors will detect a change from a north magnetic pole to a south magnetic pole.

Fig. 3-15: Phase current flow

At this precise instant, current is switched to the next winding phase. By switching current to the phase windings in a predetermined sequence, the permanent magnets on the rotor attempt to chase the current. The current is always switched before the permanent magnets catch up. Therefore, the speed of the motor is directly proportional to the current switching rate. At any instant, two windings are energized at a time with the third one off. This combines the torques of two phases at one time, thus increasing the overall torque output of the motor.

The rotor consists of a four-pole permanent magnet and a smaller four-pole sensor magnet. As the sensor magnet rotates it will activate a series of Hall sensors, located 60° apart. The sensors can be built-in photo sensors or Hall effect devices, or an externally mounted encoder (with commutation track). Either option is used to monitor the position of the shaft and to provide that information to the speed control or servo amplifier.

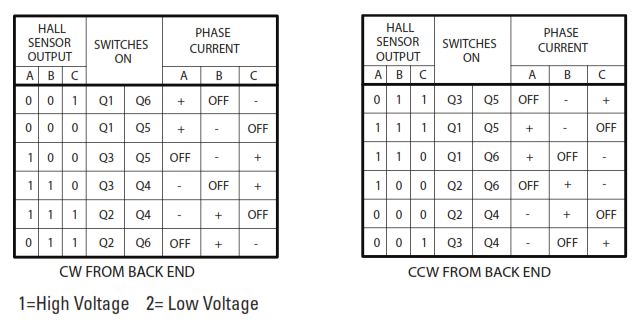

The controller logic circuits contain a binary decoder which interprets the signals from the sensors regarding the position of the permanent magnet rotor. The logic circuit outputs a specific address which tells a drive circuit (Q1 through Q6 in Fig. 3-14) which windings should be energized.

The rotation of the motor is changed within the control logic which in turn reverses the phase energizing sequence. A toggle switch is usually provided to convert the logic from clockwise to counterclockwise. Figure 3-16 shows the truth tables for both clockwise and counterclockwise commutation.

Fig. 3-16: Commutation sequence: a) clockwise (left), and b) counter-clockwise (right).

Trapezoidal vs. Sinusoidal Torque Properties: Timing of the “on’ and “off” switching of different phase pairs is determined by the signals emanating from the sensors in the motor’s commutation circuitry.

Trapezoidal torque characteristics of the phase pairs mean that fewer commutation signals are required than for a motor whose phases exhibit sinusoidal torque properties. This simplifies the control design and minimizes its cost, while providing a motor torque output with low ripple properties.

Commutation circuitry is designed to switch as the torque output and the back emf in the individual phase pairs reach their maximum (and most constant) level. This produces the least ripple effect on the output torque and the lowest phase current swing. The resulting smooth output torque makes it easier to implement digital and pulse width modulation control techniques.

Advantages: Brushless motors are more reliable, and they are a clean and quiet alternative to AC or PMDC motors. They do not have commutator or brushes to wear out, and they are virtually maintenance free. The commutation is achieved through reliable solid-state circuit components, making them ideal for applications where downtime is not acceptable. Brush sparking and associated RFI are also eliminated.

Brushless motors are not sensitive to harmonics like variable speed, three-phase induction motors. The brush noise associated with brush-type DC motors and commutators is also eliminated.

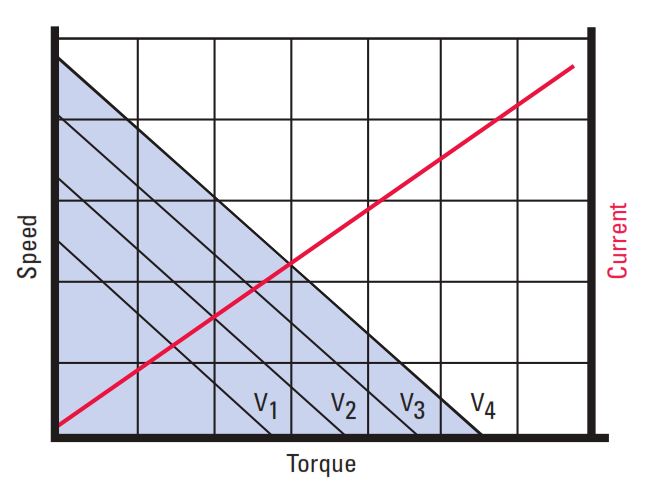

Brushless DC motors and gearmotors provide predictable performance because of their linear speed-torque characteristics. See Fig. 3-17. They can exhibit high starting torques, precise positioning capability and controlled acceleration and deceleration. And more power can be achieved from a smaller size motor.

Brushless motors can be designed with low rotor inertia. This means they accelerate more quickly in less time and offer less power dissipation during the stop / start cycle. They are also capable of operating at high speeds since there are no mechanical commutator limitations.

Fig. 3-17: Typical speed / torque curve for a brushless DC motor.

Design Considerations: Unlike conventional permanent magnet DC motors, electronically commutated designs cannot be reversed by simply reversing the polarity of the power source. Instead, the order in which the current is fed to the field coils must be reversed. Hence, a motor speed control is required. Also, due to low friction inherent in brushless motors, coasting may be a problem after the current has been removed. Special damping circuits or other devices may be added to remedy this factor.

From a cost standpoint, the electronics needed to operate brushless DC motors are relatively more complex than those of a permanent magnet DC control, and therefore more expensive than those used with conventional DC motors. With advances in electronics, and increased availability of magnetic materials for brushless DC rotors, electronically commutated DC motors have become a compatible alternative to conventional brush-type, permanent magnet DC, or variable speed AC motors and gearmotors.

Fig. 3-13A: Cutaway view of Bodine type 34B, brushless DC motor with built-in commutator, and permanent magnet rotor.

Innovative Brushless DC Motor and Gearmotor Solutions for over 25 Years!

Copyright Bodine Electric Company © 08/2013. All rights reserved.