Brushless DC (EC) Gearmotors and Motors – What Is a Brushless DC Motor?

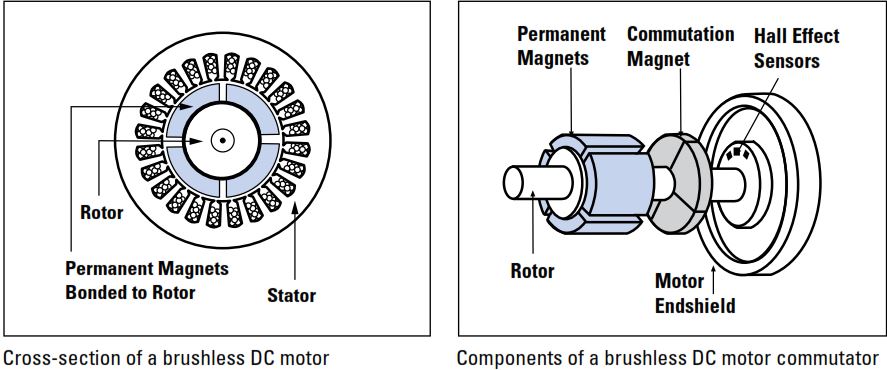

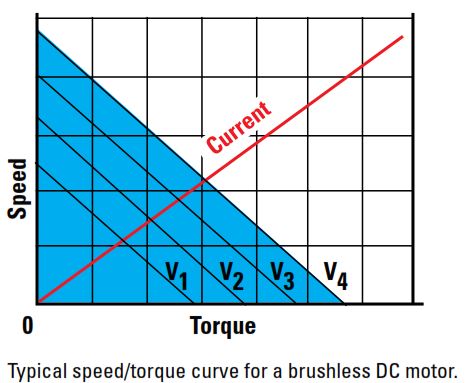

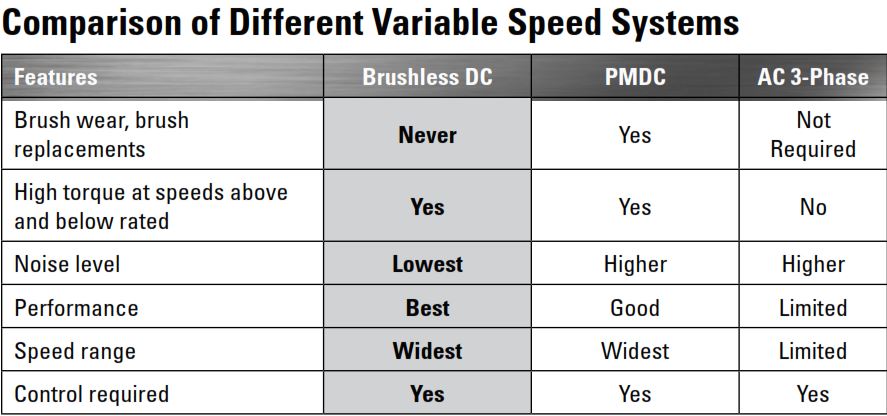

Brushless DC motors could be called “inside-out permanent magnet motors” because brushless DC motors have their magnets on the rotating part of the motor instead of on the stationary part. Accordingly, they have their windings on the stationary part of the motor instead of on the rotating part, as in a permanent magnet DC motor. Despite the differences in construction, their speed-torque curves are very similar to those of permanent magnet DC motors.

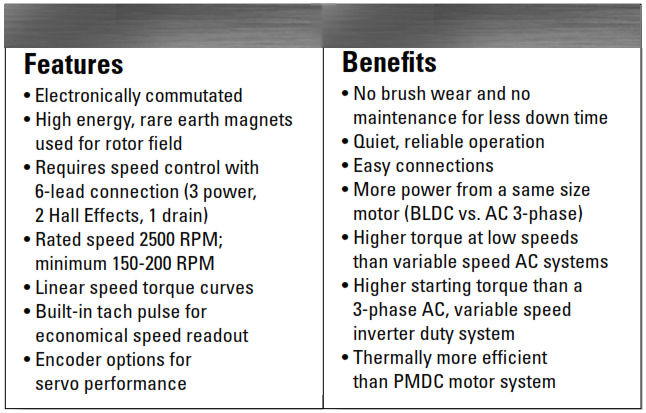

Operation of a brushless DC motor is similar to a permanent magnet motor except that the winding phases are switched on and off electronically by means of a control device. That is why we also refer to these motors as Electronically Commutated (EC). The control “knows” when to switch the windings because of feedback it receives from rotor position Hall effect sensors.

Brushless DC motors require less maintenance, provide long life, low EMI, and quiet operation. They produce more output power per frame size than AC or permanent magnet DC motors and gearmotors. Low rotor inertia improves acceleration and deceleration times while shortening operating cycles, and their linear speed/torque characteristics produce predictable speed regulation. With brushless DC motors, brush inspection is eliminated, making them ideal for limited access areas and applications where servicing is difficult or not desired. Low voltage models are ideal for battery operation portable equipment, or medical applications where shock hazards cannot be tolerated.

Applications and Industries:

- Laboratory equipment where quiet, clean, long-life operation is critical such as blood analyzers, centrifuges, mixers, shakers, MRI or cat scan equipment

- Packaging equipment for labeling, bottling, glue applicators, shrink tunnels

- Factory automation and conveyor systems

- Photocopiers, printers, and printing presses

- Pallet feeders for plastic processing

- Metering pumps for chemical treatment, lab equipment, and industrial processes

- Solar power, alternative energy sources, remote locations

- Food processing, food handling, commercial ovens

- Automated barriers, parking lot gates, door openers

Frequently Asked Brushless DC Motor and Gearmotor Questions:

Q: Can I make my own extension cable? What do I have to consider?

A: Yes, you can make your own cable, however they must have EMI and RFI shielding. Most wiring errors are due to improper or missing shielding.

Q: How long can the cable be?

A: 50 Feet maximum

Q: What is the minimum speed of Bodine brushless DC stock motors?

A: 150-200 RPM, depending on what kind of control is being used. Lower when used with a servo amplifier.

Q: What should I check first if a brushless DC motor stops working?

A: Check set-up, wire harness and connections.

Q: My red fault light is on!

A: Noise might be coming into the input of the control or there might be overvoltage to control input.

Q: Can I have preset fixed speed settings?

A: Yes, replace the pot with a resistor divider with rotary switch. Or control the analog voltage signal to the speed pot input via a PLC or other controller.

Q: Can we run faster than 2500 RPM?

A: Yes, by adjusting the MIN/MAX pot – However, the available speed range will change.

We Offer a Large Selection of Standard Products:

- Matched gearmotor-control system solutions

- 12, 24, and 130 VDC motors, gearmotors, and controls

- High speed (up to 20,000 RPM) motors and controls

- Two-year limited warranty for matched Bodine motor-control systems

- 22B/SR and 34B/FV 24VDC INTEGRAmotors™ provide integrated motor, control and feedback systems

And when a Standard Product won’t fit – Custom Solutions from Bodine:

- 48B motor achieves up to 1.5 HP with matched speed control (type EBL)

- Analog (SR) and Digital (FV) interface INTEGRAmotor options

- Environmentally protected versions for OEM applications

- Third-party markings, including Class I/Div 2

- Custom control designs available for OEM applications

To download a PDF version of this blog post, please click here.

Learn More:

Brushless DC Motors >> Brushless DC Parallel Shaft Gearmotors >> Brushless DC Right Angle Gearmotors >> 12 & 24VDC ABL (Brushless DC Speed Controls) >> Custom Class I, Div 2 Brushless DC Gearmotors >> INTEGRAmotor integrated motor/control/feedback device >>

Copyright Bodine Electric Company © 08/2015. All rights reserved.