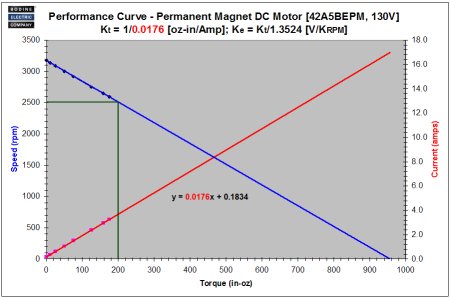

The IR compensation method is used to provide the speed regulation in our DC motor speed controls. When the load of a PMDC motor increases, the amount of current that the motor draws also increases. Per the performance characteristics of permanent magnet DC (PMDC) motors, an increase in load will cause a decrease in speed, because of the negative correlation between speed and torque (see speed-torque curve below).

IR compensation increases the voltage going to the motor, thus compensating for changes in the load, in order to maintain a constant speed at the end-user’s setting. As a reminder: In a PMDC motor, speed is proportional to the applied voltage, torque is proportional to the available current.

DC Motor Speed Controls Designed and Manufactured by Bodine (Low Voltage 0-12V, 0-24V; or 115VAC-in, 0-90V unfiltered, 0-130V filtered)

The “I” represents the current (in Amps) drawn by the motor, and the “R” represents the armature resistance (in Ohms).

Copyright Bodine Electric Company © 03/2012. All rights reserved.