Safety compliance for thermally protected electric motors:

Adding a thermal overload protector (OVLP) does not void “construction” recognition of a UL recognized (“UR” marked) AC motor or gearmotor, but it does add to the overall motor cost. If additional third-party or safety compliance markings (UL/ CSA/ CE/ TÜV/ VDE) for a “thermally protected” motor or gearmotor are requested by an OEM customer, then that additional mark (UL, CSA, or other) can be obtained at additional cost. Submitting a new thermally protected winding and prototype motors to a third-party test lab can cost up to $5000/ea and take up to eight weeks of additional development time and testing.

Design engineers at Bodine Electric Company have access to a large selection of custom AC motor windings that are already tested and UL/CSA marked for operation with a thermal overload protector – in those cases, no additional testing time or fees are incurred.

AC induction motor with manual reset, thermal overload protector (Bodine motor type 34R4BFCI, TEFC)

All stock motors and gearmotors from Bodine Electric Company carry the “UR” (UL recognized), CSA, or “cURus” (UL recognized for USA and Canada), and CE mark for “construction” only – the basic safety compliance marks according to UL1004, CSA22.2/100, or the European “Low Voltage Directive.” These marks assure the user that one does not get electrocuted when powering up an electric motor, and that the motor will not go up in flames or start a fire. Sounds like a good concept!

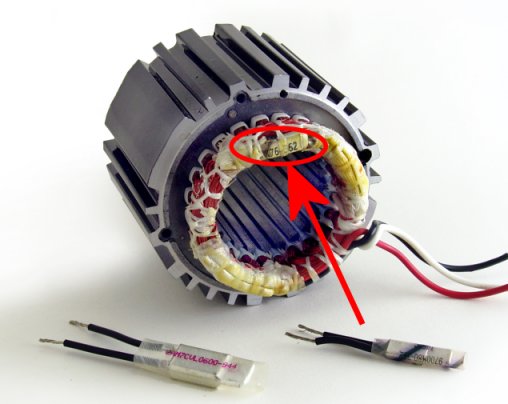

There are two ways an “automatic reset” thermal overload protector can be added to an AC induction or brushless DC (BLDC) stator. The OVLP is in series with the stator windings and opens the current in the coils if the winding gets too hot, or, the two leads of the OVLP are brought out of the motor and an external controller interprets the signal to shut off the power to the motor. As mentioned above, additional cost is only incurred when option one is chosen, and when the motor requires testing for third-party recognition for a “thermally protected” winding.

AC motor stator with on-winding thermal overload protector.

If we bring out the OVLP’s leads separately, to interface with a control, then UL testing for thermal protection would be a system issue, that is, it would have to be taken care of by the customer (since the end user or OEM is installing the motor and control system, and additional electronics or a controller are used to turn off the power to the motor, when necessary).

When an OVLP is wired in series with the stator (leads not brought out separately), different UL/CSA/IEC design and safety standards apply. And if third-party recognition for that motor or gearmotor with “thermal protection” is required, Bodine Electric or the OEM can submit that winding for testing to all applicable safety standards.

To save our customers development time and money, Bodine Electric submitted and tested several standard (stock) type 34R, 42R, and 48R [AC] windings for “blanket coverage” with UL. These standard windings were tested and approved for use with a specific “auto reset” OVLP. If the winding you require is equipped with the “blanket coverage” protector and conforms to the requirements of the UL Thermal Protection standard, then the custom built (non standard) motor or gearmotor would get a “R23” mark on the motor nameplate — to identify the UL (UR) coverage for “thermal protection” recognition.

Bodine Electric Company offers basic “construction recognition” (UL/CSA or cURus) and “CE” for all standard products, at no additional charge. When an OVLP is needed or required (typically with our AC induction motors and gearmotors), the Bodine engineering team is happy to develop a solution for you, and with you.

Types of thermal overload protectors that we use on our AC motors and gearmotors:

- single phase (off winding, two or three terminals)

- three-phase (off winding, three or six terminals, more complicated to wire into the stator, higher cost)

- automatic reset (attached to the stator coils or off winding)

- semi-automatic, or self-hold (attached to the stator coils , opens like an “auto” protector, but only closes once power to the motor was turned off)

- manual reset protector (mounted into front shield, motor housing, or t-box – with external reset button)

Thermal overload protectors used in fractional HP motors and gearmotors from Bodine Electric Company (left to right: automatic and manual reset)

Prior to my current role as manager – marketing, channel, and product development – I managed Bodine Electric’s AC and BLDC standard and custom products. As product manager, I had the pleasure of working on various projects with UL, CSA, TUV and VDE. I hope this posting provides some useful information for your next gearmotor application – when a thermally protected motor is required.

Regards, Edmund G.

(p.s.: Ja, ich spreche Deutsch, und bin ursprünglich aus dem Raum Stuttgart)

Copyright © 09/2009 Bodine Electric Company. All rights reserved.