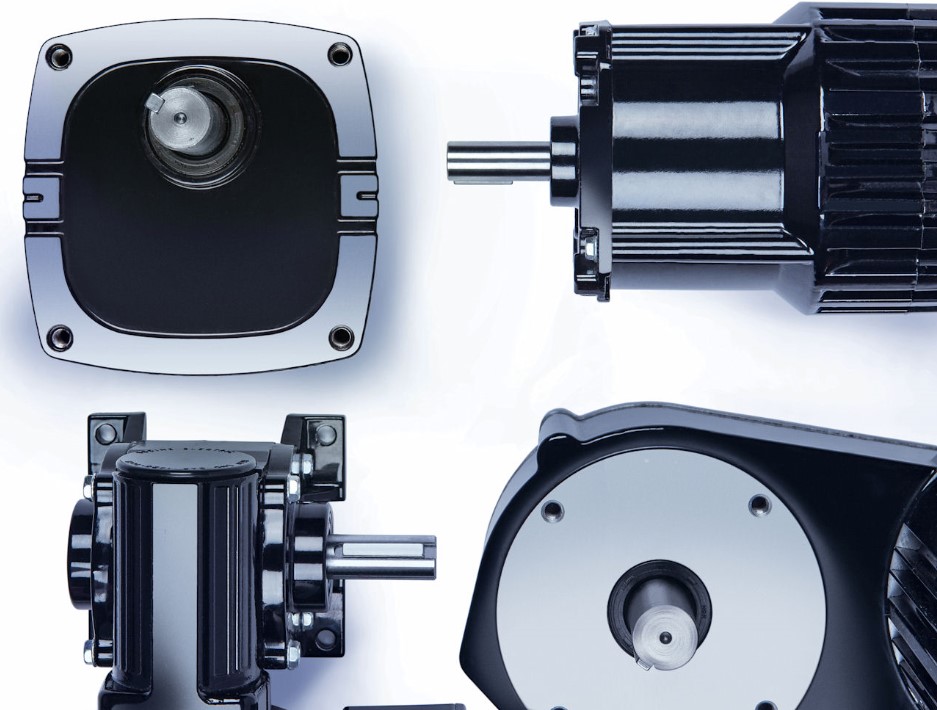

In our company history, we mention that Bodine Electric is one of the pioneers in the design and development of small (fractional HP = FHP, less than 1 HP) gearmotors in North America. Bodine Electric introduced the first integral gearmotors in the 1920s. Here is a brief discussion on how we define a gearmotor or geared motor…

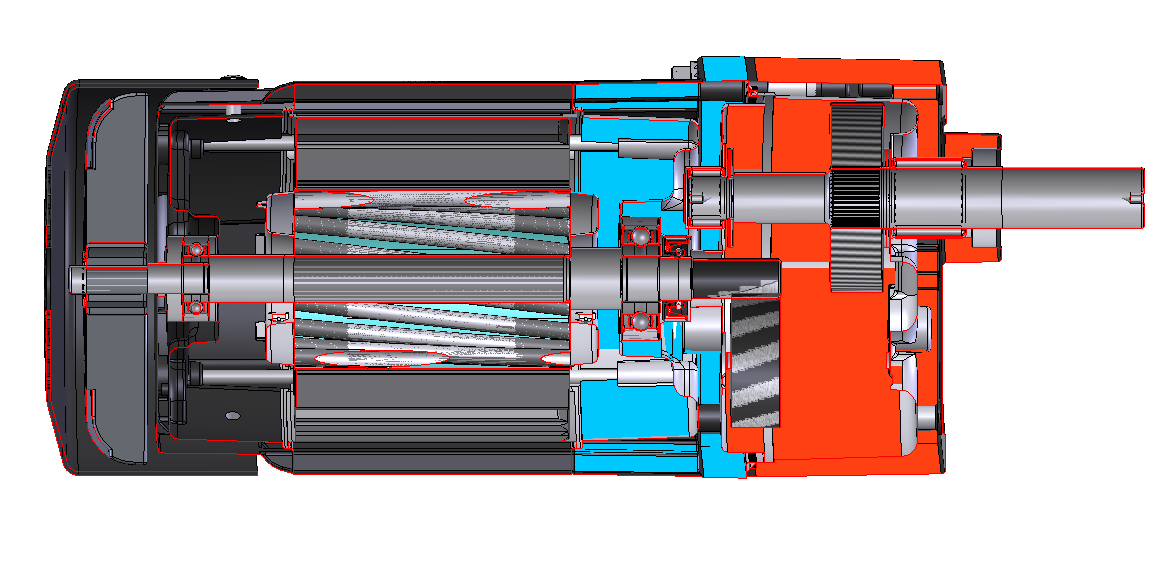

Bodine Type 30R-D AC Gearmotor (cutaway view)

What is a Gearmotor?

A gearmotor (or geared motor) is a small electric motor (AC induction, permanent magnet DC, or brushless DC) designed with an integral (non-separable) gear reducer (gearhead) attached. The end shield on the drive end of the motor (light blue, below) is designed to provide a dual function. The side facing the motor provides the armature/rotor bearing support and a sealing provision through which the integral rotor or armature shaft pinion passes. The other side of the motor end shield provides multiple bearing supports for the gearing itself, and a sealing and fastening provision for the gearhousing (orange, below). This construction offers many benefits for a user and eliminates the guesswork of sizing a motor and gear reducer on your own.

In general, gearmotors function as torque multipliers and speed reducers, requiring less motor power to drive a given load. The gear housing design, the gearing type, gear lubrication, and the specific mode of integration all affect the gearmotor performance.

Gearmotor Benefits:

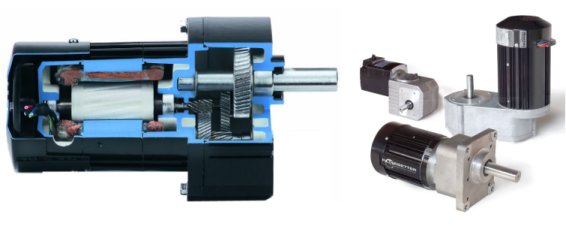

- Using the right sized motor and gearhead combination for an application helps to prolong gearmotor life and allows for optimum power management and power utilization. Traditionally, design engineers oversized motors and gearheads to add “safety factors” — Bodine “factory matched” gearmotors consistently deliver rated performance.

- Quieter operation due to integral castings and integral pinion, ground or hobbed on the armature or rotor shaft. Fewer parts requiring assembly resulting in “near perfect” alignment of the rotor, pinion and geartrain.

- Minimum risk of lubricant leakage, because of “O-ring” and lip seal construction. The design can be more compact and the lubrication can be controlled better (for various mounting configurations).

- Gearmotors eliminate the need for motor/gearhead couplings and eliminate any potential bearing alignment problems, common when a motor and gearhead are bolted together by an end-user (separable gearheads). Misalignment can result in bearing failure due to fretting corrosion.

- Separable motor and gearhead solutions make more sense in larger integral horsepower (>1 HP) applications. For example, when a 100-pound motor is mounted to a 500-pound gearhead …

Bodine type 34R-E parallel shaft gearmotor cutaway (left)

Copyright © Bodine Electric Company 2019. All rights reserved.