What is Safe Operating Torque and Speed?

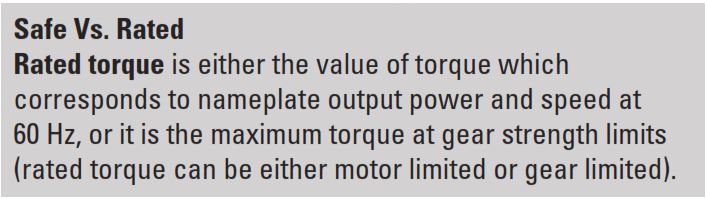

We define SOA Torque as the maximum torque at which the motor still operates within Class F thermal limits, or as the maximum torque of a gearmotor when it is gear-strength limited. Continuous duty operation must be limited to the area below the SOA or gear-limited torque curves.

The SOA torque for synchronous motors is close to the pull-in torque; that is, the motor will pull out of synchronism if the required torque exceeds the SOA torque.

The Relationship Between SOA Torque and Speed

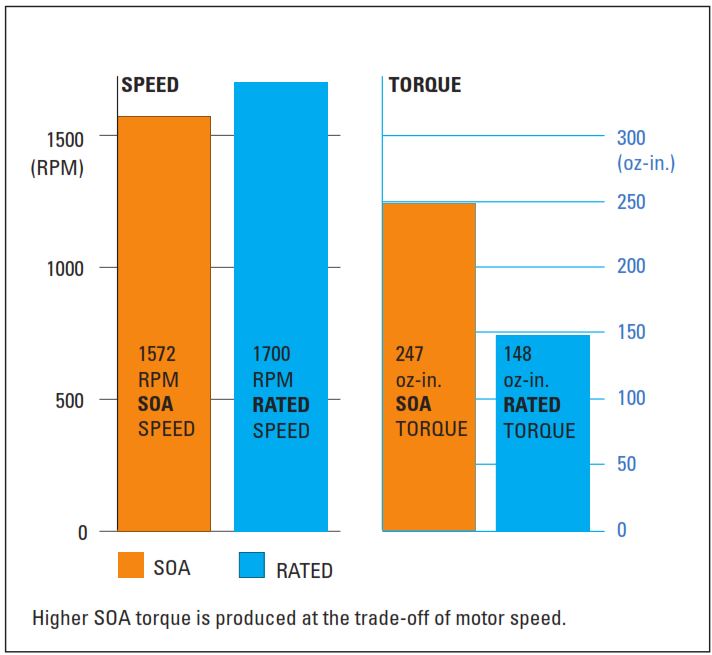

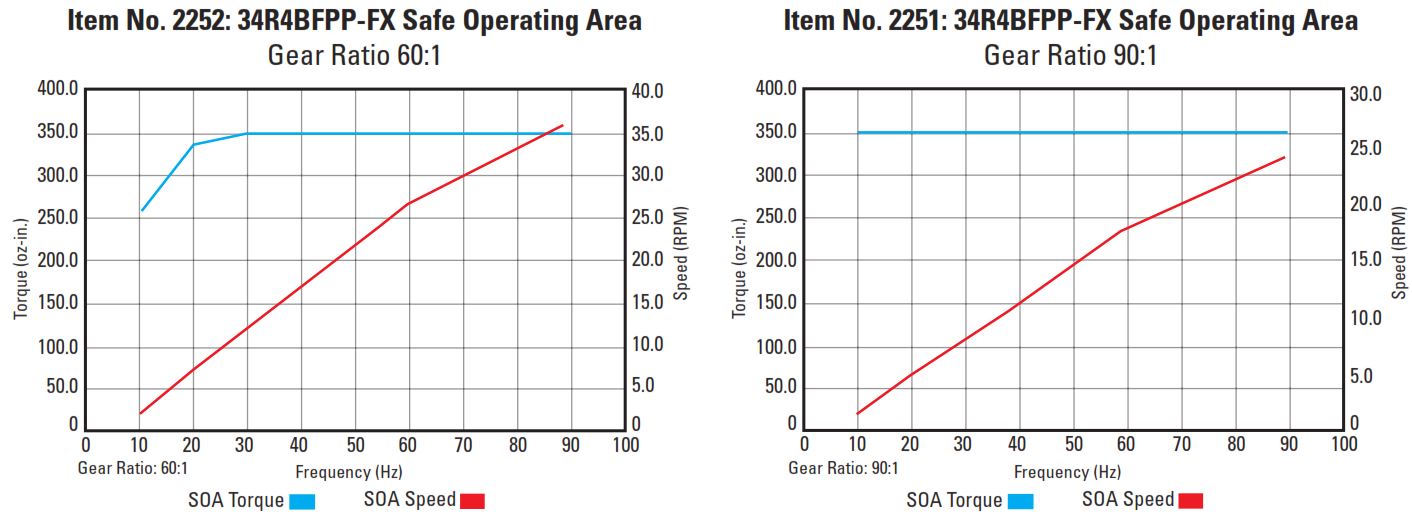

The SOA speed of Bodine’s Pacesetter™ non-synchronous motors is below rated speed. For example, Bodine model 2295, a type 34R6BFPP motor has a rated torque of 148 oz-in. at a rated speed of 1700 rpm (60 Hz), but only a SOA speed of 1572 rpm (60 Hz) at 247 0z-in. SOA torque. Higher SOA torque is produced at the trade-off of motor speed. Starting currents may be different when the motors or gearmotors are operated with an inverter drive (VFD/ASD). The SOA Graphs for Bodine Electric inverter duty, three-phase, AC induction motors and gearmotors were generated by performance-testing all standard models over the full rated speed/frequency range. The SOA graphs provide the data needed to successfully apply these variable speed AC motors and gearmotors.

Benefits

Inverter duty, three-phase gearmotors offer performance improvements over comparable single-phase units. When operated with and AC speed control (inverter), the motor or gearmotor speed can be easily matched to varying application loads. Pacesetter gearmotors and motors are more efficient than their single-phase counterparts, they are more compact, and provide higher output torques in the same size package. In addition, these variable-speed AC gearmotors and motors don’t require brush replacement or brush maintenance, and the gearheads are lubricated for life.

To download this blog article as a PDF, please click here.

Copyright Bodine Electric Company © 01/2019. All rights reserved.