Application Notes

We design and manufacture thousands of standard and custom AC, brushless DC and permanent magnet DC gearmotor solutions. These application notes provide practical tips for the use and installation of our products.

IP-69K Stainless Steel AC Worm Gearmotors

Engineering Tips

Most stainless steel gearmotors are rated IP-66 or higher, and are typically hermetically sealed to prevent water or particle ingress from frequent high-pressure washdowns. The IP-69K rating is defined via two industry standards: IEC 60529, Degrees of Protection Provided by Enclosures, which defines IP69 as, 6 = dust tight and 9 = high pressure water jet resistant.

.jpg)

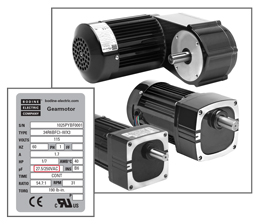

Gearmotor Selection and Application Guide

Engineering Tips

We review the construction, operating variables, and different types of fractional horsepower (FHP) “integral” gearmotors. Some of the topics covered in this guide are: gearmotor mounting orientation, impact of lubricant on gearhead life, duty cycle considerations, gearhead efficiency and noise, gearhead life, Brush life, ambient temperature…

AC Inverters (VFDs) For Variable Speed Applications

Engineering Tips

Inverter drives (also called variable frequency drives) allow AC inverter-duty gearmotors and motors to run at variable speeds. The DC voltage is “chopped” by power transistors (IGBTs) at high frequencies to simulate a sine wave that is then sent to the motor. Varying the output voltage and frequency of the control changes the speed of the motor...

Benefits of Hypoid Gearmotors

Engineering Tips

Right angle gearmotors with hypoid gearsets have several advantages when compared with standard worm-and-pinon right-angle gearmotors. Hypoid gearmotors are more efficient, produce less heat, provide higher torque, and are usually smaller than equivalent gearmotors with worm-and-pinion reducers.

Remote Operation of a 34B/SR-WX Gearmotor in Non-Hazardous Locations

Engineering Tips

This application note explains the steps to properly wire our standard 34B/SR-WX, 12/24VDC gearmotors for remote operation in a non-hazardous location...

.jpg)

Safe Operating Area (SOA) Ratings of AC Inverter Duty Gearmotors Explained

Engineering Tips

We define SOA Torque as the maximum torque at which the motor still operates within Class F thermal limits, or as the maximum torque of a gearmotor when it is gear-limited. Continuous duty operation must be limited to the area below the SOA or gear-limited torque curves. The SOA speed of our inverter-duty non-synchronous AC 3-phase motors and gearmotors is...

Introduction to Planetary Gearmotors

Engineering Tips

Planetary gearheads are typically comprised of a sun gear, a ring gear, and a planet carrier assembly with three to five planet gears per stage. Planetary gear trains are popular in applications where more torque is required from a smaller gearmotor package.

What is a Synchronous AC Motor?

Engineering Tips

The difference between the speed of the rotating magnetic field of an induction motor (which is always synchronous) and the speed of the rotor is known as "slip". When the rotor design enables it to "lock into step" with the field, the slip is reduced to...

Introduction To Worm Gearing

Engineering Tips

Worm gearing is a proven and economical solution for applications that require high speed reductions in limited space, and with very smooth and quiet operation. Worm gears have inherent self-locking ability depending on design and ratio. Our latest Application Note provides an overview of...

Electromagnetic Holding Brakes for FHP Gearmotors

Engineering Tips

Holding, or "Power-Off" brakes provide extra safety in applications where the load must remain in position in the event of power loss or equipment failure. Our design engineers have helped OEMs develop brake systems for hundreds of AC and DC applications, from home stairlifts to...

Sizing a Fuse for a Bodine Gearmotor, Motor or Speed Control

How-To Instructions

This application note explains the benefits of fuse protection and provides an overview of how to specify fuses for our AC, PMDC and BLDC products...

How to Connect a Reversing Switch to a 3- or 4-Wire (PSC) Gearmotor

How-To Instructions

This application note shows how to wire an optional switch to reverse the direction of a 3- or 4-wire Bodine permanent split capacitor (PSC) motor/gearmotor. All the wiring diagrams use variations of a double throw switch, with a center-off position. The purpose of the center-off position is to...

How to Connect a 3-Wire Reversible AC Gearmotor (and optional switch)

How-To Instructions

These connection diagrams show how a 3-wire reversing PSC gearmotor/motor can be connected with the use of a relay to existing 4-wire PSC motor circuitry. Connection diagrams and direction of rotation changes between gearmotors with...

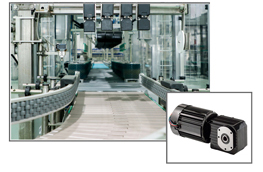

Sizing and Selecting Gearmotors for Conveyor Applications

Engineering Tips

This application note provides step-by-step instructions for how to size and select a gearmotor in a belt-driven conveyor application. Before sizing a gearmotor, you must first know...

Connecting a 3-Wire Reversible PSC Gearmotor into a 4-Wire System

How-To Instructions

This application note shows how a 3-wire reversible PSC gearmotor/motor can be connected with the use of a relay to existing 4-wire PSC motor circuitry. Connection diagrams and direction of rotation changes between gearmotors with...

How to Connect a 4-Wire Reversible AC Motor or Gearmotor (and T-box)

How-To Instructions

All our permanent split capacitor (PSC), AC single-phase motors and gearmotors require a run capacitor to operate. This application note will show you how to wire the PSC motor and...

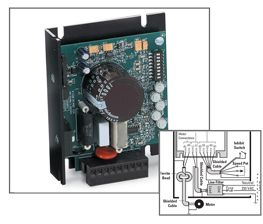

Selecting DC Motor Speed Controls for PMDC Gearmotors

How-To Instructions

For DC motor proper speed control, you will need to identify which performance criteria are important to your application. This application note will review how different speed controls affect...

Filtering Tips For Bodine type WPM and UPM Controls in Industrial Machines

Engineering Tips

Follow these guidelines when installing Bodine type WPM and UPM controls in equipment or applications that are sensitive to Electromagnetic Interference (EMI).

Design Considerations for Gearmotor Applications

Engineering Tips

To select the best gearmotor for an application, you must go into more detail than just selecting the best suitable output speed and torque. This application note covers five criteria you should consider: mounting orientation, gearhead efficiency, self-locking...

Selecting FHP Gearmotors for Long-Life Applications

Engineering Tips

When specifying a fractional horsepower (FHP) gearmotor, first you should decide what kind of operating life is needed from your FHP gearmotor. This application note will help you choose the best product based on total operating hours, design life, output torque...

Introduction to Motor Constants for Fractional Horsepower Gearmotors

Engineering Tips

Motor constants are needed to calculate permanent magnet DC (PMDC) or brushless DC (BLDC) motor specifications and ratings, or to match the motor properly to an amplifier. The motor constants are required in order to predict the PMDC or BLDC motor’s performance with changing variables...

Measuring Armature Circuit Resistance in PMDC Motors

How-To Instructions

When a permanent magnet DC (PMDC) motor fails to operate properly or fails to run at all, one sensible troubleshooting step is to calculate the armature circuit resistance. This application note shows the steps necessary to...

Load Testing – Know Your Current, Know Your Load

Engineering Tips

When designing a new piece of equipment that uses a gearmotor, design engineers must calculate how much motor torque will be needed to drive their application load. This application note provides a procedure to load test your application. A good way to determine how much load is on a motor or gearmotor is to...

Motor Windings – Custom and Standard Options

Engineering Tips

Winding design is one of the major factors that determines gearmotor performance. We offer a wide selection of standard gearmotors and motors with the most common voltage and frequency ratings for both the North American and International markets. This application note explains the differences between...

Troubleshooting a Brushless DC (ECM) Motor and Control System

|

Typical Operating Conditions for AC Gearmotors and Motors

Engineering Tips

Learn how operating a gearmotor or motor above or below the ratings shown on its product nameplate can affect performance. For standard gearmotors, the torque rating shown on the product nameplate (or in the manufacturer’s sales literature) represents a complete gearmotor rating and reflects the capacity of the limiting gearmotor design elements. Some of the design limitations considered are: motor input power, strength or wear rating of the gearing…