Gearmotors for Packaging Equipment

Our team of design and application engineers is ready for your next design challenge. We supply rugged, high-performance gearmotor solutions to many OEMs in the packaging industry and understand the demanding performance requirements for packaging machines where downtime is not an option. To get you started, we offer over 1,500 standard/stock products with gear ratios from 4:1 to 3600:1, torque to 1000 lb-in (113Nm) and horsepower up to ¾ hp (560W). But if a stock product doesn’t meet your application requirements, we are more than happy to talk with you and your team about a custom solution. Talk to an Application Engineer.

Gearmotors Packaging Equipment (PDF)

Featured Applications:

PRIMARY PACKAGING

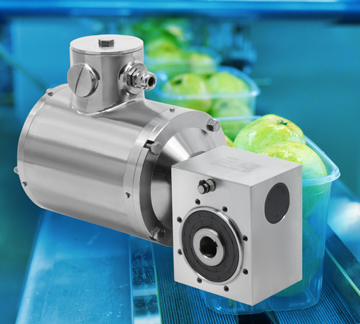

Gearmotors in Contact with the Packaged Contents

In primary packaging, gearmotors can be in close or direct contact with the contents of the packaging. If those contents are liquids in a bottling machine or raw meat in a food processing line, then the gearmotor must either be protected from liquid spillage or be able to endure repeated washdowns. Bodine Electric Company has different gearmotors with different levels of protection for these different applications.

SECONDARY PACKAGING

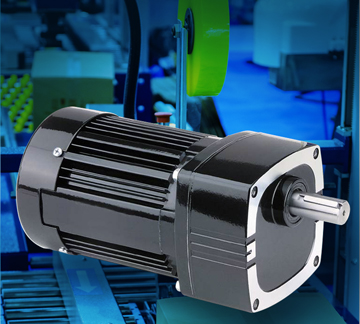

Gearmotors That Run Continuously for Multiple Shifts

Secondary packaging machines erect cardboard boxes, fill the boxes with cushioning material around the contents, and tape the boxes shut. These machines require a gearmotor that is durable enough to run continuously all day long. All gearmotors made by Bodine Electric Company are designed for long, trouble-free continuous duty operation, but the one most commonly used in secondary packaging machines is our type 42R-FX. The single phase AC parallel shaft gearmotor has been powering secondary packaging machines for as long as there have been secondary packaging machines.

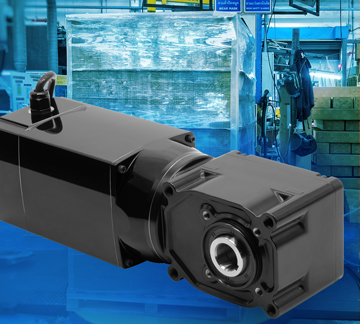

END-OF-LINE PACKAGING

Strong Gearmotors for a Tough Job

End-of-line packaging equipment is used to contain multiple cartons on a single pallet. Strapping and shrink-wrapping systems often use gearmotors with torque ratings in excess of 1000 lb-in. Bodine Electric Company has several gearmotor product lines with torque ratings that high, including the type HG and CG, and our new type 42R hypoid right angle hollow shaft gearmotor.

AC Induction Gearmotors for Simple Applications

The simple, zero-maintenance design of AC induction gearmotors makes them ideal for single-speed applications that demand non-stop operation such as box sealing equipment. During peak production, a box sealing conveyor line might be turned on once and left to run all day as box after box passes through it. Because these machines run in only one direction, there is no need for reverse switches, speed controls, complex wiring, position sensors, or dynamic braking.

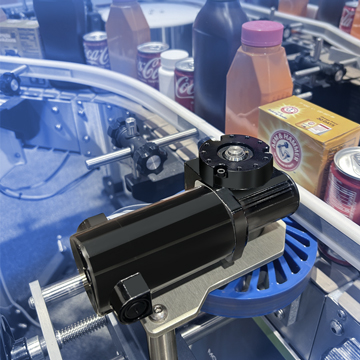

Brushed DC Gearmotors for More Complex Applications

Brushed DC gearmotors are more complex than AC induction gearmotors. They are constructed with a commutator and replaceable brushes and require a speed control to operate from an AC power supply. They are ideal for applications that involve adjustable speed, frequent starts-and-stops, dynamic braking, and reversing, such as a rotator on bottle labeling equipment. As bottles move down a packaging line, rotators position them so that a label is applied correctly. The rotator is needed infrequently, so it is turned on and off repeatedly for short periods. The short duty cycle makes brush wear inconsequential for the expected life of the machine.

Brushless DC Gearmotors for High Tech Applications

Brushless DC gearmotors feature rare earth magnets and hall sensors instead of brushes. They require a motion controller for commutation. These gearmotors are found in high-tech servo applications that involve closed-loop positioning, velocity control and rapid-fire starting and stopping such as packaging equipment that surrounds a product with kraft paper, bubble wrap or expanding foam. Encoders are frequently used in conjunction with brushless DC gearmotors to determine position, speed, and direction.