One of the conveniences of using a “power off” (spring-loaded) DC holding brake is that it can be wired in parallel with the motor power leads so that it will engage when power is removed from the motor. Most times this works as expected, however here are a couple of special cases to keep in mind:

1) When power is removed from the motor (and brake), the gearmotor/motor acts as a generator as long as the armature is rotating. If the load has any inertia or momentum, it can still generate enough power to keep the brake from engaging right away. Eventually the armature speed decreases due to load friction and the brake can engage, but this could take milliseconds or seconds depending on the type of load. Usually not a problem, but good to be aware of the possibility.

2) In cases where the gearmotor load requires a high starting torque, the armature can draw a lot of current from the power source. If the leads are longer than a couple of feet, then the voltage drop along the wires could be enough that the brake doesn’t disengage right away. This makes the motor power through the load AND the brake and possibly creates premature wear on the brake disk.

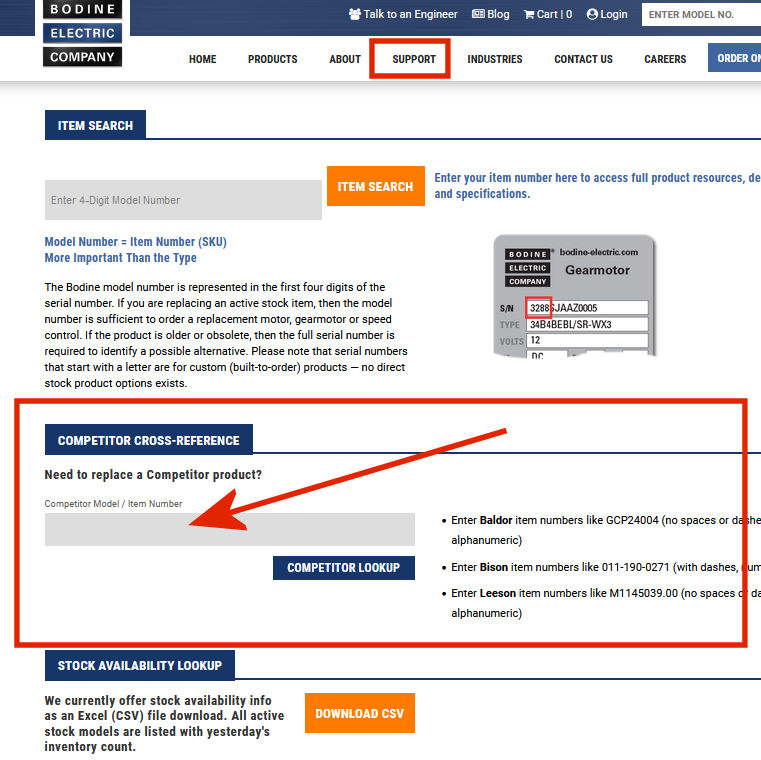

If you are looking to cross a Baldor, Bison, or Leeson gearmotor you can now do so on our customer Support web page.

Each competitor part number is constructed differently:

For example, if you are crossing a Baldor item, the part number will look something like this GCP24004, please do not add any additional spaces, dashes, or any type of alphanumeric characters to the search box as this will not bring up the correct information.

Bison part number, e.g. 011-190-0271, please enter the P/N with dashes just like this and the results will appear for you.

Leeson part number, e.g. M1145039.00, please enter it like this, do not include any spaces, dashes, or additional alphanumeric information.

We can provide possible replacements for many of the obsolete AC fixed speed, AC inverter duty or PMDC fractional horsepower (<1HP) gearmotors from Baldor. We also offer a large selection of “SCR Rated” PMDC gearmotors that are rated for either 90VDC or 180VDC. To get started, please provide the Baldor catalog or item number of the gearmotor in question. Baldor part numbers often start with either GPP, GP, GMP, but there are many other variations (you’ll find the part number on the motor nameplate).

With that information, we’ll be able to identify the closest possible Bodine stock gearmotor. If our replacement option is not a drop-in, we’ll let you know what the differences are. For OEM machine builders with larger quantity requirements, we can also develop a custom gearmotor solution that will be a direct drop-in. Please contact our regional sales manager to set up a design and application review for a custom drop-in gearmotor or motor, or send an e-mail to our technical support team at info@bodine-electric.com.

We define “SCR Rated” as a permanent magnet DC gearmotor that is designed to operate with an unfiltered SCR speed control while delivering similar speed and torque performance as a PMDC gearmotor that is designed to be operated from a filtered DC speed control or from a PWM speed control. SCR rated PMDC gearmotors or motors are designed to remain within their safe operating temperature range while delivering full rated torque over the entire speed range (when operated with an unfiltered SCR speed control). This is in contrast to PWM-rated PMDC gearmotors or motors which would need to be operated at reduced torque if they were operated with an unfiltered SCR speed control.

The majority of our standard stock 130V PMDC motors and gearmotors are rated for operation with a filtered speed control (FF = 1.0) at an armature speed of 2500 rpm. When operated with an unfiltered SCR control (90VDC off 115VAC), these stock motors will run at an armature speed of approx. 1725 rpm and would have to be proportionally derated. Hence, offering 90V or 180VDC “SCR Rated” gearmotors with an armature speed of 2500rpm allows the user to use the same gearmotor and gear ratio with either a winding for a filtered (PWM) or unfiltered SCR controls.

Form Factor for a DC speed control is a measure of the amount of current (ampere) filtering (smoothing) provided by the control to a motor. Form Factor cannot be determined until a motor and control combination are driving a load. However, most control manufacturers catalog their controls with a FF rating. Most small motor and control combinations exhibit FF= 1.0 to 1.05 with a filtered control and FF= 1.6-1.8 with an unfiltered control at rated torque.

Bodine permanent magnet DC motors in this catalog are rated for continuous duty on 130 VDC, FF=1.05 current as supplied by Bodine type FPM and WPM controls. These motors and gearmotors can be successfully operated from unfiltered controls at FF=approximately 1.6, at speed not less than 1700 rpm. For intermittent duty operation, full nameplate torque may be available. The designers should test for each individual application.

Brush life will depend on current density, duty cycle, and environmental conditions. The absolute best estimate of brush life comes from data obtained while operating in the application. The brush inspection interval and process (if needed) may be included in the operating manual for the equipment which has the Bodine product installed. However, if such guidance is not available from the OEM, then we recommend that brush inspection be carried out at regular intervals of 4-6 months, or 1000 hours, depending on how many hours a day the motor operates. Assuming that all variables (i.e., current density, duty cycle, environmental conditions) are reasonably consistent, brush life should be fairly linear. It’s important to remember that one brush will wear more than the other if the motor only operates in one direction (i.e., CW or CCW), so both brushes should be checked for wear. Once you establish a brush wear rate for your unique application, you can adjust your inspection intervals accordingly.

Most AC and PMDC motors and gearmotors, the INTEGRAmotors, and most speed controls carry the CE mark. For model-specific details, please contact our customer service department.

Our Control Selection Guides (PDF) can help you select the right speed control for your Bodine gearmotor or motor application. We offer speed controls for most of our variable speed AC inverter-duty (3-phase), Permanent Magnet DC (PMDC) and Brushless DC (BLDC/EC) stock models:

Yes, we currently offer Class I/Div.1 (Ex-Proof) and Class I/Div.2, brushless DC and AC three-phase, inverter-duty, and PSC gearmotors. We stock (40) Class I/Div. 1 explosion-proof 34B-FX gearmotors and (4) AC & BLDC CI/D1 motors. Special lead-times apply. Please contact your local Bodine

Yes, Bodine has manufactured custom motors and gearmotors with mounted brakes for many decades. Minimum order quantities apply. Please contact your local Bodine

All motors and gearmotors shown in our catalog are reversible. To prevent gearing damage, most gearmotors require a full stop before reversing.

Obtainable torque is the maximum output torque (peak torque) for a gearmotor. Gearmotors may be operated at these levels only for brief periods due to thermal or mechanical limitations.

The rated (nameplate) torques for stock gearmotors and motors shown in our catalog and on our website are for continuous duty operation. And while our standard/stock products are rated for continuous duty operation, they can also be used intermittently. Operation at loads higher than nameplate ratings is possible for short periods as long as there are rest periods for cooling. Loads higher than obtainable torque for gearmotors are never recommended. The temperature of the motor should be monitored during testing to make sure it is not overheating.

Obtainable torque is the maximum output torque (peak torque) for a gearmotor. Gearmotors may be operated at these levels only for brief periods due to thermal or mechanical limitations.

All Bodine stock gearmotors and motors are designed so that rated (nameplate) torque, shown in our catalog and on our website, is safe for continuous duty operation. These continuous duty stock products can be used intermittently, as well. Operation at loads higher than nameplate ratings is possible for short periods as long as there are rest periods for cooling. Loads higher than obtainable torque for gearmotors are never recommended. The temperature of the motor should be monitored during testing to make sure it is not overheating.

Obtainable torque is the maximum output torque (peak torque) for a gearmotor. Gearmotors may be operated at these levels only for brief periods due to thermal or mechanical limitations.

AC three-phase inverter duty (PP), three-phase synchronous inverter duty (YP), and some permanent split capacitor (PSC or CI) designs may be operated at adjustable speed with suitable controllers.

Adjustable speed systems are sometimes appropriate for single speed applications. If the desired speed is not known or not offered in a single speed product, an adjustable speed system may be set to the desired speed. For a low volume requirement, this approach will normally be more cost effective than changing ratios or making up special gearing.

A synchronous motor is an induction motor that operates directly from AC power or from a variable frequency drive (VFD), and rotates at an exact multiple of the line frequency (or set speed). Common synchronous induction motor speeds at 60 Hz are 1800 RPM (4-pole) and 3600 RPM (2-pole). A unique feature of the AC synchronous motor is that there is no rotor "slip." The rotating magnetic field in the stator and the magnetic field in the rotor are "locked" in step as long as the load on the output shaft is within nameplate ratings.

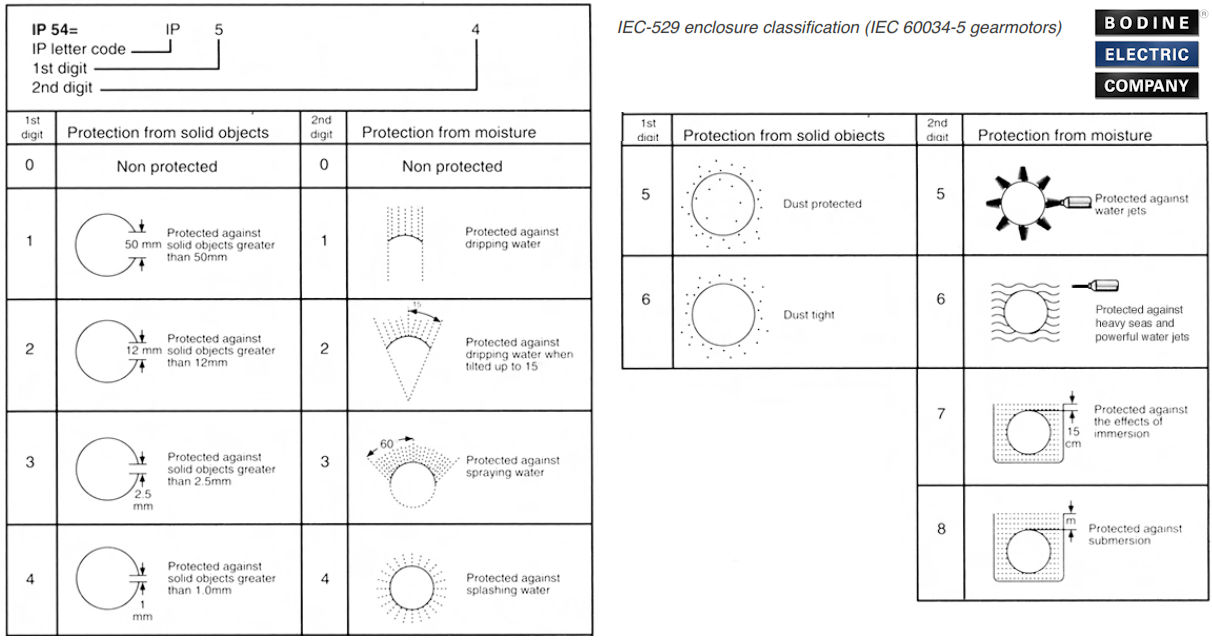

The IP (ingress protection) number is based on the international IEC system for rating enclosures. An IP-44 rating is roughly equivalent to NEMA 12 for dust and water resistance. IP-44 means that the gearmotor or motor housing is protected against solid objects greater than 1 mm, and against splashing water.

Our stock motors and gearmotors are typically rated IP-20 to IP-40. If you want to increase the ingress protection rating of our gearmotors and motors to IP-44, you can install our optional terminal box kits -- models 0984, 0985 or 0986. We also offer boot kits for our PMDC 24A, 33A and 42A motors.

Most 24A stock gearmotors and motors are rated IP-20, but we offer an IP-44 seal kit. The part number of this IP-44 seal kit is stock model 0976. Our type 24A-60P planetary gearmotors are rated IP-65 and do not require this kit

Self locking refers to the tendency of some gearing to resist movement when the gearmotor is at rest and the load is attempting to move. An example is a load on a conveyer belt trying to drive the system backwards. Right angle gearheads with ratios greater than 20:1 are often considered to be self locking.

Parallel shaft gearheads and right angle gearheads with low ratios are generally not considered to be self locking. Right angle gearheads with ratios greater than 20:1 are often considered to be self locking. They will resist movement up to their torque rating. As the gearing nears the end of its useful life or if it is subjected to overload conditions, it may wear to the point where it is no longer self locking. Self locking gearing is not a recommended method for preventing movement in applications.

Motors without gearing and K-2 gearmotors may be operated in any position. Standard Bodine gearmotors are designed for universal horizontal mounting with the motor portion or the drive shaft horizontal. Other mounting positions are possible, depending on the gearmotor type (and lubricant). Some gearmotors are oil lubricated. If these gearmotors are mounted in a position other than horizontal, the oil might find its way out of the gearbox as the motor shaft or the shaft seal wear out over time. When in doubt, please consult our technical support staff in Northfield (Chicago area). You can e-mail us at info@bodine-electric.com.

A motor designed for 60 Hz operation will run at 5/6 rated speed on 50 Hz. This can be of concern for totally enclosed, fan cooled (TEFC) motors or gearmotors. For example, a motor rated 1700 RPM on 60 Hz will run at 1400 RPM on 50 Hz. When the motor fan runs slower, the motor winding will receive less then the expected cooling.

Bodine 60 Hz permanent split capacitor (PSC) "Cl" motors will run hotter on 50 Hz, and typically require a capacitor change and derating. The motor temperature should be monitored during testing to make sure it is not overheating. Bodine split phase (or "Sl") motors and gearmotors that are rated for 60Hz should not be operated on 50 Hz because the internal centrifugal cut-out switch will not cut out correctly and might damage the start winding. Consult the factory for a 50Hz solution.

Operation of more than one motor from a single control is not normally recommended (PMDC or BLDC). However, when cost is a primary concern, a multiple motor/single control system with either permanent magnet motors and control or 3 phase motors and control may be successfully implemented. More than one AC three-phase, inverter duty motor/gearmotor may be operated with a single AC speed control (=inverter, = adjustable speed drive), as long as the sum of the motor currents does not exceed the rated output current of the control. Motor speeds should not fluctuate as long as the motors are not overloaded and the sum of the motor currents does not exceed the rated output current of the control.

Radial load is a force pushing or pulling the side of the output shaft. It is shown in the diagram (at right) as Fr. Exceeding the allowable radial load for a motor or gearmotor will cause premature wear of output shaft bearings and gearing and could cause the shaft to break. Fr may be the result of a weight on the shaft, belt tension or torque transmitted through a belt, chain, gear, or certain flexible couplings. Our catalog shows the permissible radial load for each motor and gearmotor. In calculating these values, the following assumptions were made:

- The radial load is in the worst case direction, i.e. pushing or pulling the shaft sideways.

- The motor or gearmotor is delivering rated torque.

- The radial load was applied at distance "d" from the hub or mounting surface. Higher radial loads may be applied closer in on the shaft. Lower radial loads are permitted further out on the shaft.

Flexible couplings are often used to avoid radial load. Most flexible couplings are designed so that they do not transmit radial load, however this should be verified by the coupling manufacturer.

Axial load is a force on the output shaft into or out of the motor or gearmotor. It as shown in the diagram (at right) as Fa. Exceeding the allowable axial load for a motor or gearmotor will cause premature wear of output shaft bearings and gearing.

.gif)

Most of our standard products are fully coated with a black finish on all exterior surfaces. Some stock gearmotors are partially painted, and some custom OEM products might not be painted at all (dependent on the application and operating environment). For a given motor or gearmotor type, the motor components have the same physical dimensions, but paint or coatings on external surfaces will add to the overall dimensions. The paint thickness is not reflected in the dimensions on our online CAD drawings, and it could be up to 0.006 inches thick on each painted or coated surface. Different components may feature different surface coatings: we typically powder coat our castings, some parts are anodized, and stators with exposed laminations are either wet painted, or have an e-coat surface finish (e.g. 22B, 30R, K-2 stators).

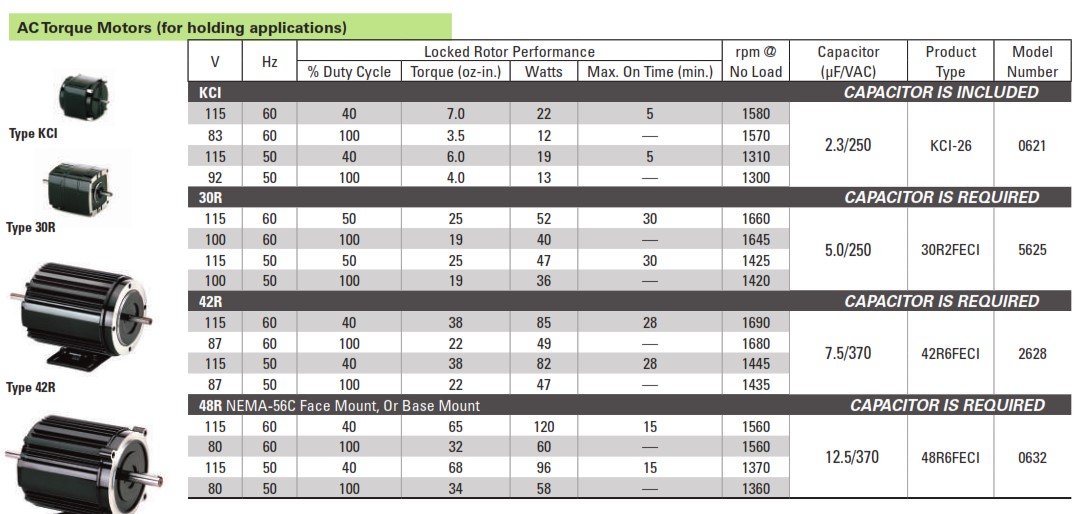

Bodine offers AC induction motors that are impedance protected - we call these types of motors AC Torque Motors. These motors are ideal for tensioning applications because they can operate in stall mode without overheating. Torque motors feature: Higher starting torque at lower speed and lower running torque, and the ability to run in stall mode without Overheating (impedance protection).

What does "impedance protection" mean? It means that the motor winding temperature stays within its thermal limits when it is stalled. If the motor needs to be operated in 100% stall mode, then the operating voltage has to be reduced to x% of the rated voltage (see our stock catalog S, page 20 for details).

Application Example: Tensioning a web, wire or film in an unwind or rewind application. In these types of applications, the motors act like an "electronic spring".

It does not matter how voltage is supplied to the torque motor, as long as the average voltage supplied is per the motor’s specifications. Some options that you can use are: a step-down transformer or an inverter with single-phase output. See our stock catalog S, page 20 for reduced voltage specifications.

It depends on why you are measuring the current. A DC current reading will be a good estimate you can use to size the motor for a torque rating. If you want to measure current in order to determine whether or not your motor/gearmotor is sized adequately (i.e. you want to load test your motor/gearmotor by measuring current and calculating torque from measured current), use a DC current reading.

An AC current reading will be essentially the same as the true RMS current through the motor. This is a better measure of the current that is flowing through the motor. This measurement will be more useful if you want to determine the amount of dissipated heat the motor is producing.

No. We choose the optimum value capacitor for use with your permanent split capacitor (PSC) motor/gearmotor. It might be acceptable (consult Bodine Electric first) to use a capacitor with a higher voltage rating, but it is NOT recommended that the capacitance value be changed. The capacitor in a capacitor motor circuit changes the reactance of the auxiliary winding to charge up torque. Changing the capacitance value will change the reactance of the whole winding circuit. If there is an urgent need for a difference capacitance value (ex. correct size capacitor is not available immediately), you may be able to do the follow (consult the Bodine Electric Company before doing so):

Use a lower MF capacitor if running the motor/gearmotor at continuous duty.

Use a higher MF capacitor if running the motor/gearmotor at intermittent duty.

Note: Changing the capacitor’s capacitance value will affect the motor/gearmotor performance. You may lose torque (consult Bodine Electric Company for more information for your specific application).

However, it remains Bodine’s recommendation that you do not change the capacitor that is specified for use with a specific motor/gearmotor.

The winding type is shown on the heading of each selection table for each product. It is also included in the Bodine Frame Type as a 2 letter code. On a motor, it is the last 2 characters. For example, Bodine Frame Type 42A5BEPM is a "PM" or Permanent Magnet. On a gearmotor, it is the 2 characters before the dash (-). For example, Bodine Frame Type 34R6BFCI-W2 is a "Cl" or Permanent Split Capacitor Motor. The Technical Discussions at the beginning of each section in our catalog provide more information on the characteristics of the winding types in the section.

We recommend this custom design feature for applications where the machine design requires high starting torque. These special AC induction motors with torque core rotors deliver: Higher starting torque at lower speed and lower running torque.

The brushless DC (BLDC) motors/gearmotors are the quietest of all of our technologies. They are then followed by the AC motors/gearmotors – specifically the three phase and permanent split capacitor motors first and followed by the split phase motors. The Permanent Magnet DC (PMDC) motors will run the loudest of all three technologies. Bodine values itself on high quality, quiet motors and gearmotors. “Loud” is relevant, and application-specific, but all of our motors and gearmotors, in all three technologies, should run efficiently and quietly.

The standard brushless motors/gearmotors have a 60 degree commutation. Some BTO (Built-to-Order) motors/gearmotors have 120 degree commutation. If in doubt, please contact our Inside Sales team with your serial number.

The maximum backlash for our standard/stock parallel shaft (helical/spur) gearmotors is 3 degrees. The backlash also depends on the number of gear stages and the gearing type. Some of our parallel shaft gearheads use only helical, some use spur and helical, and some use Nylon and steel gear combinations. In general, we cut and finish all our gearing to AGMA 9 specifications, and we typically see a backlash of 1.5 degrees or better in most of our stock products. Bodine also offers planetary BLDC and PMDC gearmotors that have a standard backlash of < 60 arc minutes.

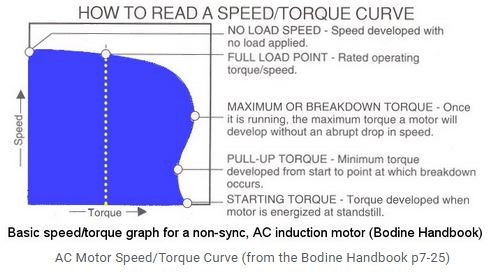

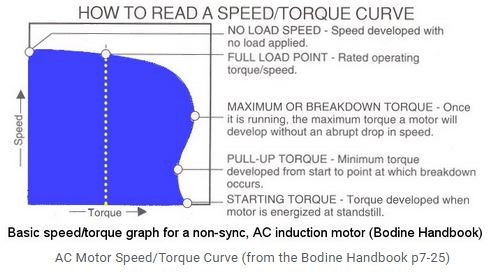

IR compensation is what provides the speed regulation of the control. When the load on a PMDC motor increases, the amount of current that the motor draws also increases. Per the performance characteristics of permanent magnet DC motors, an increase in load will cause a decrease in speed, because of the negative correlation between speed and torque (see speed-torque curve below). The IR compensation increases the voltage going to the motor, thus compensating for changes in the load, in order to maintain a constant speed at the end-user’s setting regardless of load variations.

No, you cannot run 2 PMDC motors/gearmotors on one PMDC control. The IR compensation in the control cannot communicate with 2 motors. PMDC applications require a one:one ratio of motor:control.

No, it does not. A voltage measurements across A1 and A2 (if the motor/gearmotors is not loaded) on our type WPM controls will result in low voltages because of the transistors on the output of the control that turn power on and off for the PWM signal. Because of these transistors, you must be connected to a load to see the expected 0-130VDC.

Our enclosed type FPM controls use different boards than the chassis type FPM controls. The boards are very similar and have identical functional abilities, but the boards within the enclosures have some physical characteristics that are not on the chassis control. There are replacement boards available for the standard enclosed type FPM controls.

The part numbers are as follows:

Models 81X (X = 5,6,8) – part no. 43100451

Models 83X (X = 5,6,8) – part no. 43100483

Models 85X (X = 5,6,8) – part no. 43100485

Contact an authorized distributor to purchase these replacement boards. A distributor locator is available online at http://www.bodine-electric.com/Asp/Distribuloc.asp.

The 5VDC supply on our type WPM controls was not designed to do much more than provide power to the main speed potentiometer. You may use it to power something else, but will not be able to get much current out of it. We only use .5mA from this supply, which is the optimal maximum current. You may be able to pull 1mA, but at your own risk. If you pull 2mA, you will definitely damage the board. Please proceed with caution if you do plan on using this power supply to source power to any of your components. Note that using this supply as a source of power is out of the rated specifications of this control and will void your Bodine warranty.

A filtered control provides the motor with cleaner DC power than the one supplied by the unfiltered control. Also, when used with an unfiltered control vs. a filtered one, the motor will most likely run hotter (at the same load point) and will have shorter life. The unfiltered control provides a 130VDC motor with a maximum voltage of 90VDC, which means that the speed of the motor will not reach the nameplate rating, it will be 9/13th of that.

Yes, you can use a digital signal on the 3984 to control direction, disable, etc inputs. The digital signal must be from an open collector type device that is capable of sinking a 10mA minimum current and withstanding 12VDC. The 10mA is the minimum value for the open collector device, and is the typical current that is going to be used by the circuit. Anywhere up to between 30mA and 50mA on the open collector device is acceptable to use.

You can use the Red Lion Cub 5 Series digital rate meter. This will provide you with a digital readout of the speed at the motor/gearmotor driveshaft, from the tachometer output on the control. The rate meter is battery powered, and can be programmed to know how many pulses it will receive per unit output and to display speed in RPM. Our tachometer output provides the meter with 12 pulses/motor revolution. To calculate the resolution of the tachometer output with respect to the driveshaft of a gearmotor, multiply the gear ratio by 12.

Yes, it is possible to run more than one AC motor/gearmotor on one AC control. Note: some conditions must be met before you are able to do so. First, the motors/gearmotors must be 3-phase and inverter duty. Second, the continuous output current of the control must be greater than or equal to the sum of the rated motor currents.

Yes, we do offer a potentiometer kit for our AC controls. It is Bodine part number 43301002. These controls use a 5kW potentiometer. Please contact one of our authorized distributors to purchase this kit.

The carrier frequency of model 2999 is 16kHz, which provides high motor efficiency and low motor noise. See page 9 in the user manual: Jumper J12 is used to select the drive’s switching frequency (8 kHz or 12 kHz) for different torque modes. See p.19: Torque Mode Selection (J10 and J12) – Jumper J10 is factory set to the “CT” position for Constant Torque Mode, which is desirable for most machine applications and Jumper J12 is set to “8K” (8 kHz switching frequency). For Variable Torque Mode, used for HVAC and fan applications, set Jumper J10 to the “VT” position and set Jumper J12 to the “12K” position (12 kHz switching frequency reduces audible motor noise). See Figure 25 in the user manual.

The carrier frequency of Bodine’s AC chassis, and NEMA-1/IP-40 drives (models 2982, 2983, 2984, 2987, 2998) is 16kHz.

The NEMA-4X/IP-65 control (model 2999) has a carrier frequency that is factory pre-set at 16kHz for high efficiency and low motor noise. This model has a jumper J12 that is used to select the drive’s switching frequency (8 kHz or 12 kHz) for different torque modes. Consult the user manual for details.

The carrier frequency is the switching frequency of the transistors used to create the PWM signal. Lower switching frequencies will result in the motor dissipating less heat, therefore running cooler. At the same time, the motor will produce more noise, therefore running louder. As the switching frequency increases, the amount of heat the motor dissipates will also increase, but the noise it produces will decrease.

Bodine does not currently carry any single-phase inverters. Note: our single phase motors/gearmotors do not have inverter duty insulation.

All of Bodine’s potentiometers are one-turn pots. If you need any other type (i.e. multiple-turn pot), it must be sourced separately.

Technically, the answer is yes. However, if the continuous output current on your control is less than that of the motor’s nameplate rated current, you will run into current limit and will not get the full nameplate rated torque from the motor.

No, brushless DC motors cannot be run with an AC VFD. The brushless motor needs electronic commutation, and this will not be provided correctly from a VFD. The motor design will not work with a VFD. It may be possible, through some experimenting, to get the motor to turn, but there will be zero torque out.

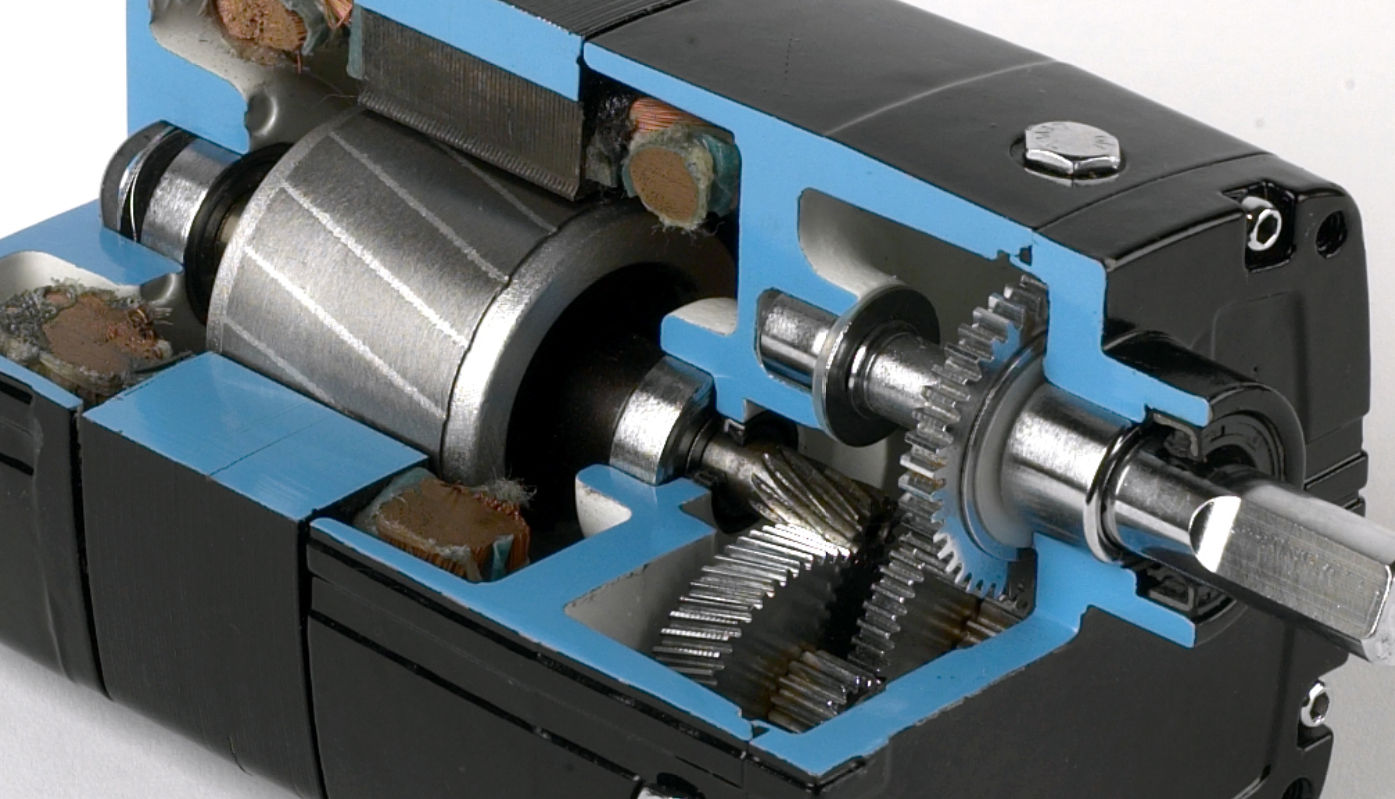

Gearmotors are ideal for applications that require high output torque in the smallest possible drive package, or when the motor output speed needs to be reduced. Their high torque-to-size ratio makes them the ideal drive solution for tight spaces, or when the overall machine design needs to be optimized for the smallest possible motor footprint. The inherent benefit of integral gearmotors is that they function as torque multipliers and speed reducers, requiring less motor power to drive a given load. The gear housing design, the gearing type, gear lubrication, and the specific mode of integration all affect the gearmotor performance, and application suitability.

You can purchase gearmotors directly from our website our from our extensive, global distributor network. Bodine Electric offers the broadest line of standard/stock fractional horsepower (FHP) gearmotors, motors, and speed controls (1/200 HP to 3/4HP).

- We have over 10,000 AC, PMDC and brushless DC electric motors, gearmotors and system matched motion controls in stock at our Peosta, Iowa (USA) warehouse.

- You can also order accessories (mounting brackets, terminal boxes, shaft kits, etc.) as well as replacement parts (brushes, springs, brush caps for our PMDC products)

- Most orders with premium routing (air shipments) ship the same day, if an order is entered before 1:00 p.m. CST, or within 24 hours (ground shipments).

- Orders shipped securely via UPS with order tracking.

- International orders ship via UPS Worldwide Express with order tracking.

- For quantity discounts, contact your local authorized Bodine distributor or your Regional Bodine Sales Manager.

Brushless DC (BLDC) gearmotors are typically quieter than PMDC gear motors or inverter-duty AC three-phase gearmotor and motor designs. PMDC gearmotors have carbon brushes that continuously “rub” on the commutator of the motor armature. This interaction, along with the DC power from an unfiltered SCR or PWM speed control can result in audible noise. Similarly, inverter-duty, variable speed AC motors and gearmotors emit some noise created by the PWM voltage supplied to the motor from the inverter (PWM speed control). Gear housing style and design, as well as the number of gear stages can also affect overall noise emitted from the gearmotor. Worm gearheads (right-angle gearmotors) are generally quieter than inline or parallel shaft gearmotors due to the differences in gear geometry and how the gear sets interact.

All our gearmotor, speed control, and gearmotor accessory user manuals, and our installation instructions can be downloaded from the Literature sections of our website. You can find them under the Support tab > Literature > User Manuals. We also offer a large collection of application notes that cover many frequently asked user questions. Also under the Support tab and in the Literature section are links to download our many product info sell sheets, our product SDS (safety data sheets) for gearmotor lubricants, and our main product catalog “S” and the Bodine Handbook.

Yes, it is possible to run more than one AC three-phase motor/gearmotor with one AC speed control (VFD).

Note: The motors/gearmotors must be AC 3-phase and inverter-duty. Second, the continuous output current of the speed control (variable frequency drive) must be greater than or equal to the sum of the rated motor currents.

Download our informative Gearmotor Selection and Application Guide – then consider these basic design criteria to determine which gearmotor is right for your application

- Intermittent vs. Continuous Duty

- Speed and Torque

- Gearhead Life

- Output Torque

- PMDC vs BLDC or AC power

- Mounting Orientation

Order quantities and annual usage will factor into our pricing model for direct and indirect OEM customers. Besides volume discounts for repeat OEM orders and applications, we work with our OEM customers to optimize most of our gearmotor designs to meet your specific application needs. Design modifications can be made to improve performance or IP rating for customer-specific operating conditions, to add custom windings or mounting features, or to cost-reduce a design by eliminating unwanted design features. Please contact your regional Bodine sales manager to discuss your specific target price or application requirements. We look forward to hearing from you!

Inverter-duty gearmotors (and motors) feature variable speed, AC three-phase motor windings that are designed with a special winding insulation system to protect them from potential voltage spikes or corona damage caused by the AC “inverter” PWM speed control (Variable Frequency Drive / VFD). The special inverter-duty windings meet NEMA motor standard MG 1, Section IV, Part 31. In general, AC three-phase gearmotors and motors are more efficient than their AC single-phase counterparts, they are more compact, and provide higher output torques in the same size package. In addition, these variable-speed AC gearmotors and motors don’t require brush replacement or brush maintenance. Typical Applications are conveyor systems, food processing equipment, factory automation, pumps, lifts and packaging equipment.

AC Speed Control (VFD) Basics:

AC inverter-duty (variable speed) gearmotors feature either 230 VAC or 230/460 VAC AC 3-phase windings, specifically designed with an inverter rated insulation system. Our AC speed controls require minimal set-up and no programming. Most Bodine inverter-duty gearmotor customers use our gearmotors in open-loop velocity control applications, like conveyors, feeders, or metering pumps. The V/Hz inverters (VFDs) are the most basic type of drive. V/Hz drives use a pulse-width-modulation scheme to create an output roughly approximating a sine wave of variable frequency, with its amplitude, or voltage, proportional to set frequency. The speed range on V/Hz drives is limited and torque is not easily controlled.

PMDC Speed Control Basics:

Basic PMDC motor speed controls accomplish the conversion of AC power to DC with varying degrees of DC voltage “purity” (see FAQs on Form Factor). For proper control selection you’ll need to identify which performance criteria are important to your application. There are four basic types of PMDC speed controls.

1. The unfiltered half-wave Silicon Controlled Rectifier (SCR) control is the most basic design. The unfiltered full-wave SCR control places a single SCR in series with the DC motor’s armature winding. This converts the AC into DC by simply blocking the negative half cycle of the AC sine wave. The SCR control produces a fairly choppy output for the motor and only faintly resembles a true DC current.

2. The unfiltered full-wave SCR control improves on the unfiltered half-wave SCR control by adding another SCR and two diodes to form a bridge rectifier, instead of just blocking out the negative half cycle of the AC sine.

3. The filtered full-wave SCR control design utilizes a large filter capacitor that is placed across the output of the control. Since a capacitor stores energy during the rising portion of the AC sine wave and then discharges it slowly during the falling portion, it effectively smoothens out the choppy output current created by the switching of the SCRs. As a result, a smooth output current is produced that approximates pure DC.

4. A filtered Pulse Width Modulation (PWM) control uses a different method to produce a smooth output current that is comparable to that of a filtered full-wave SCR control. The AC supply is first rectified and filtered before it is switched on and off to vary the output voltage. In contrast, the filtered full-wave SCR control simultaneously rectifies and switches the AC supply, then filters it after switching.

See our Application Notes page for more details on Speed Control Selection: https://www.bodine-electric.com/application-notes/

BLDC Speed Control Basics:

In a brushless DC (BLDC) motor, the magnetic field rotates, while the BLDC motor rotor is equipped with high-energy permanent magnets (4- or 8-pole). Commutation (60° or 120°) occurs electronically by switching the (three-phase) stator current direction at precise intervals in relation to the position of the rotating magnetic field. Solid state or PWM speed controls and internal feedback devices are required to operate brushless DC motors (also called: electronically commutated “EC” motors)

Brushless DC motors combine characteristics of both PMDC and AC three-phase motors. They are similar to AC motors in that a moving magnetic field causes rotor movement or rotation. They are similar to PMDC motors since they have linear speed-torque performance characteristics. Brushless DC motors and gearmotors are more reliable, and they are a clean and quiet alternative to AC Inverter-Duty or PMDC motors. They do not have a commutator or brushes to wear out, they emit minimal electronic and audible noise, and they are virtually maintenance free. The commutation is achieved through basic PWM speed controls, making them ideal for applications where downtime is not acceptable. Because of the more complex electronic commutation scheme, the BLDC speed controls tend to cost a little more that AC or DC drives.

Bodine cares about user safety, and about the environment. We strive to have all our products comply with RoHS, REACH and Conflict Mineral regulations. Most of our products are UL recognized for the USA and Canada, and carry the cURus mark. Some products are UL listed for USA/Canada. Click here, to see information on our UL Safety Compliance, RoHS, REACH, and ISO9001 certification.

Product safety is essential and hard-coded into our corporate DNA. Most of our products are UL recognized for the USA and Canada, and carry the cURus mark. Some products are UL listed for USA/Canada. Click here, to see our UL File numbers, and how to access the information on the UL server.